Recent Purchase

View All

Customer Reviews

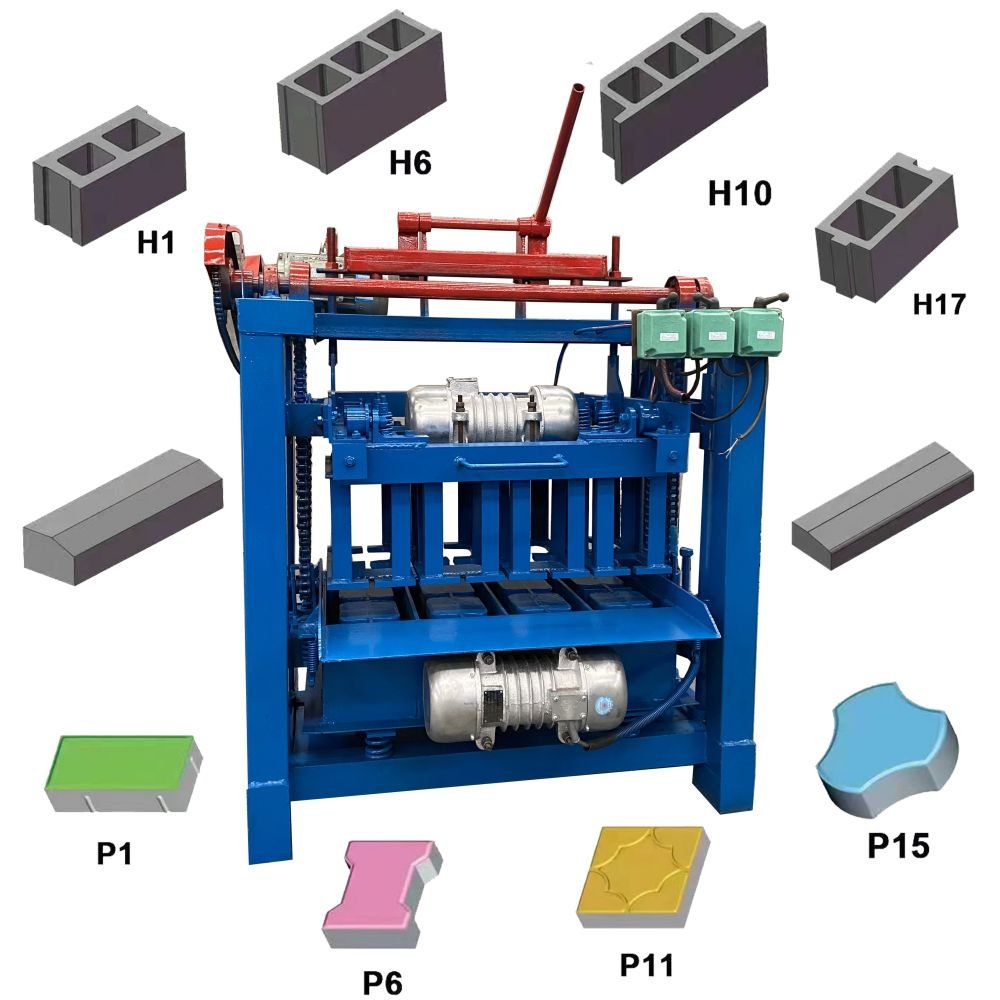

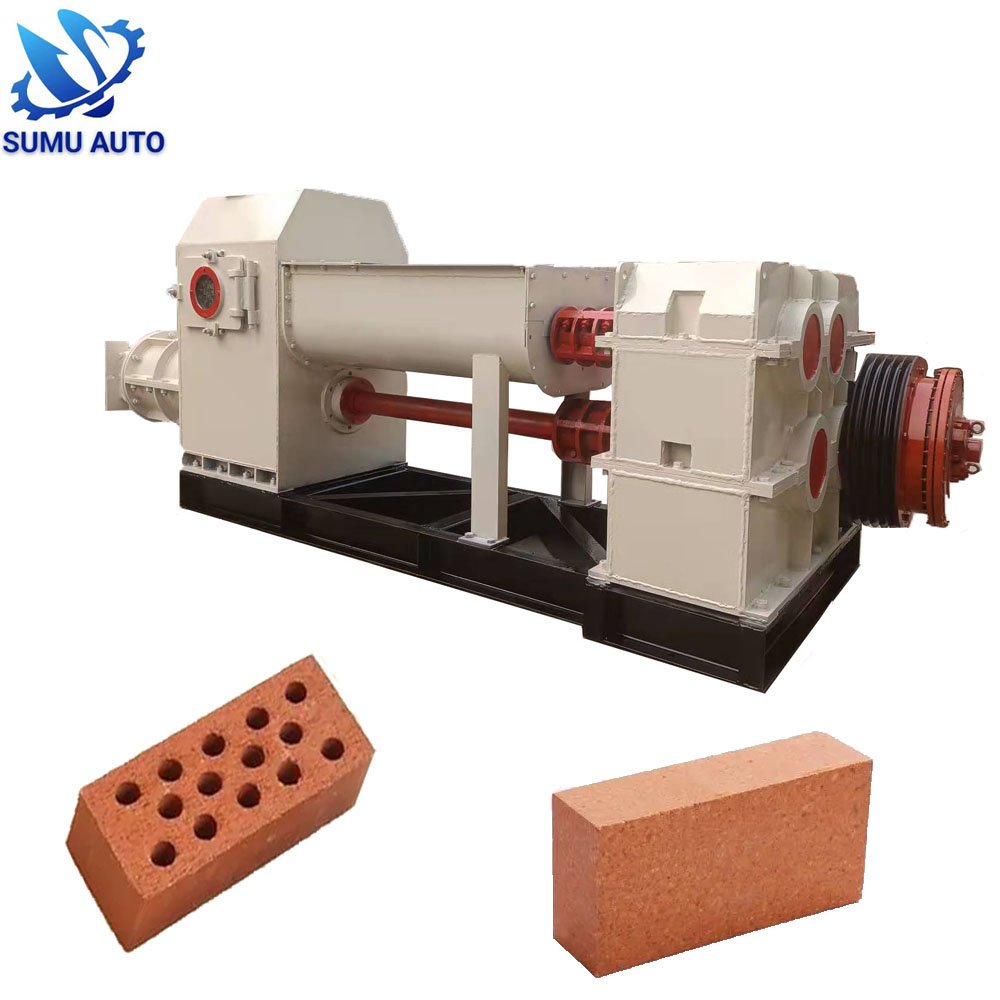

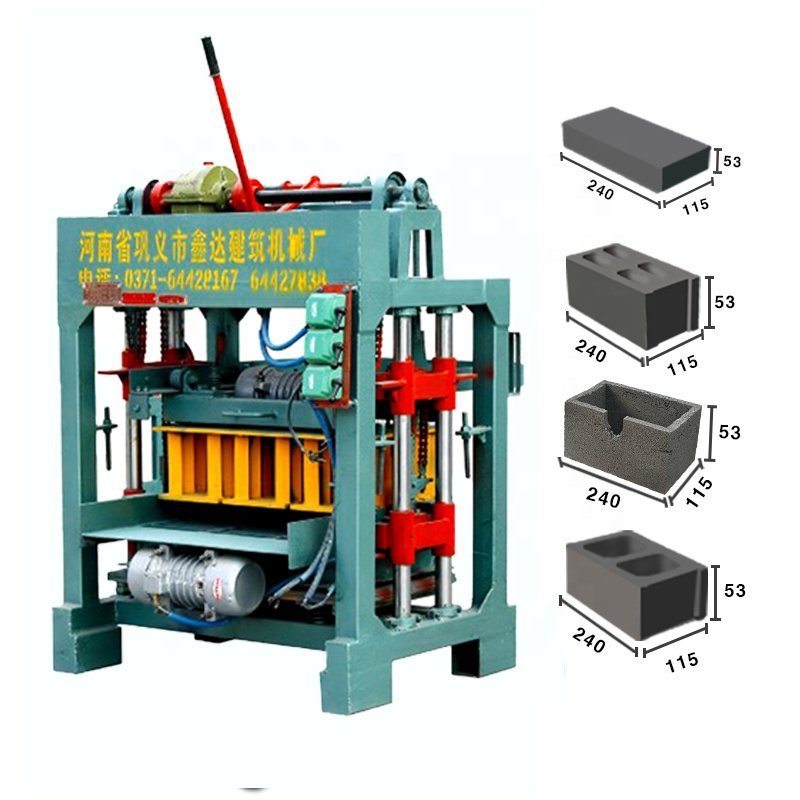

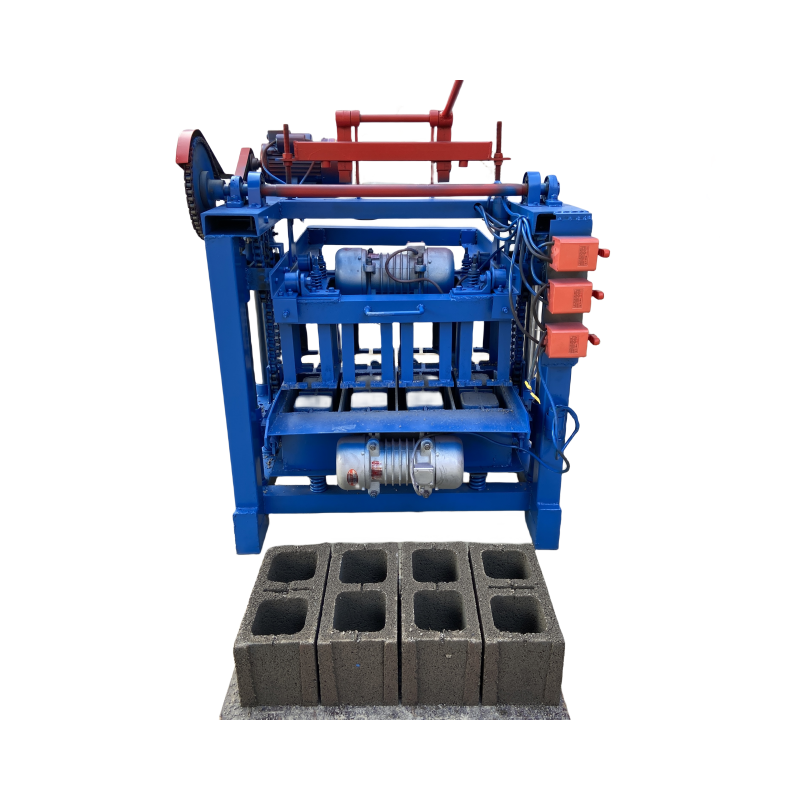

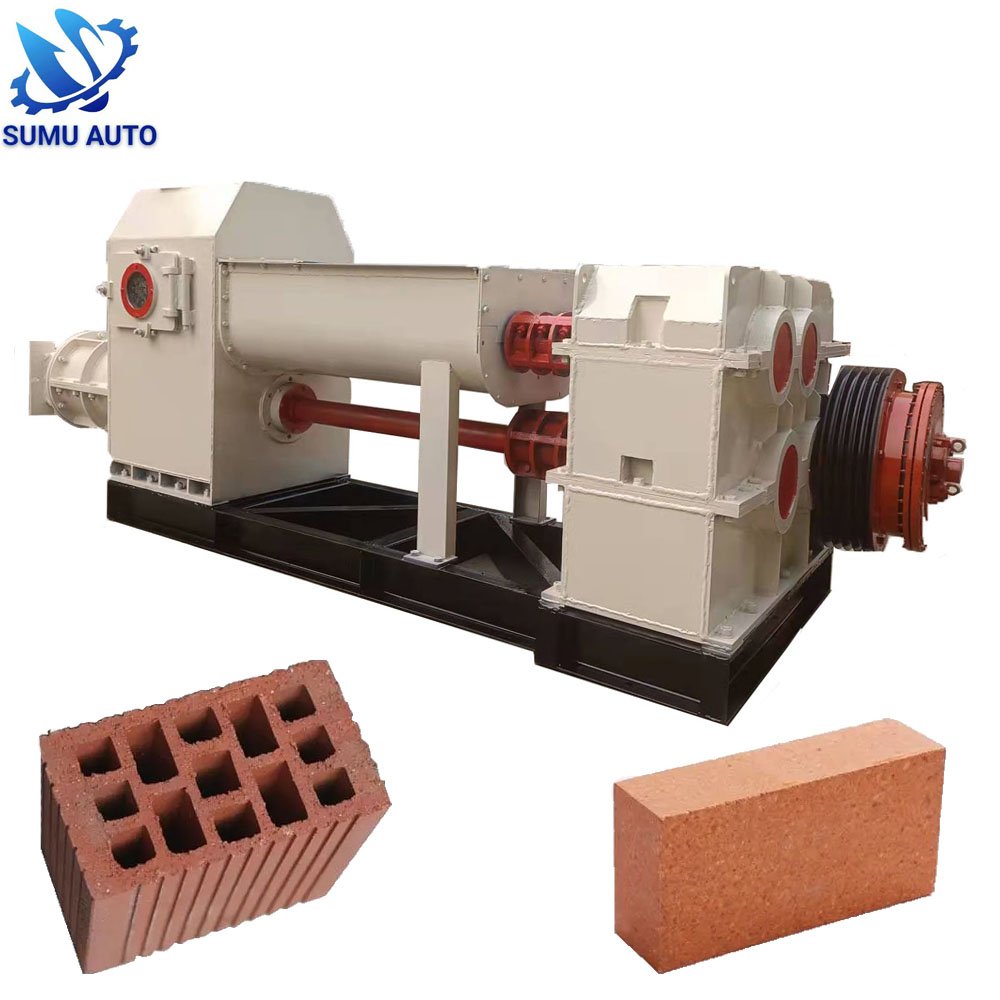

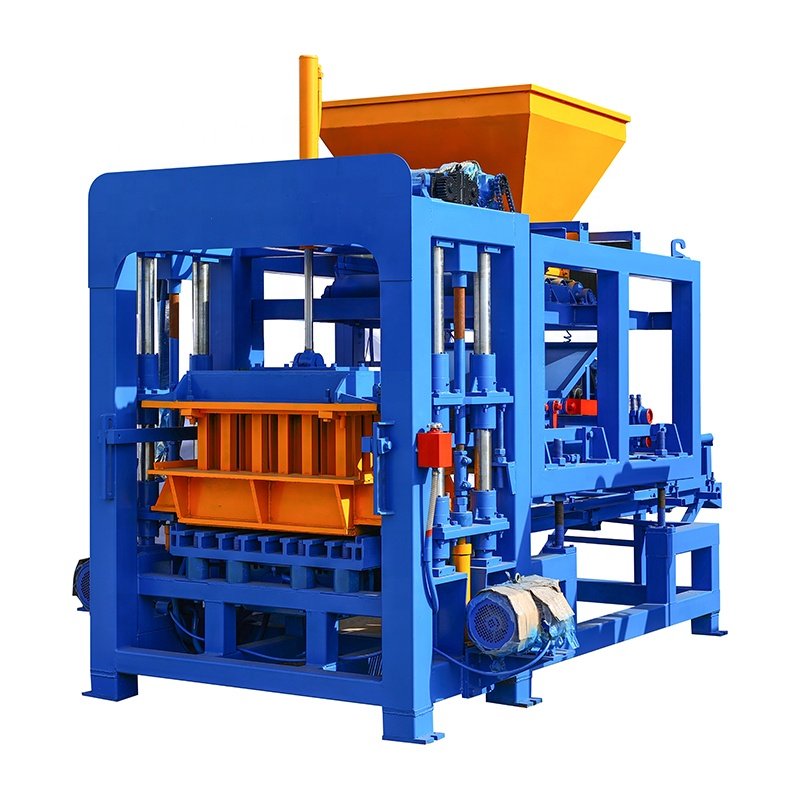

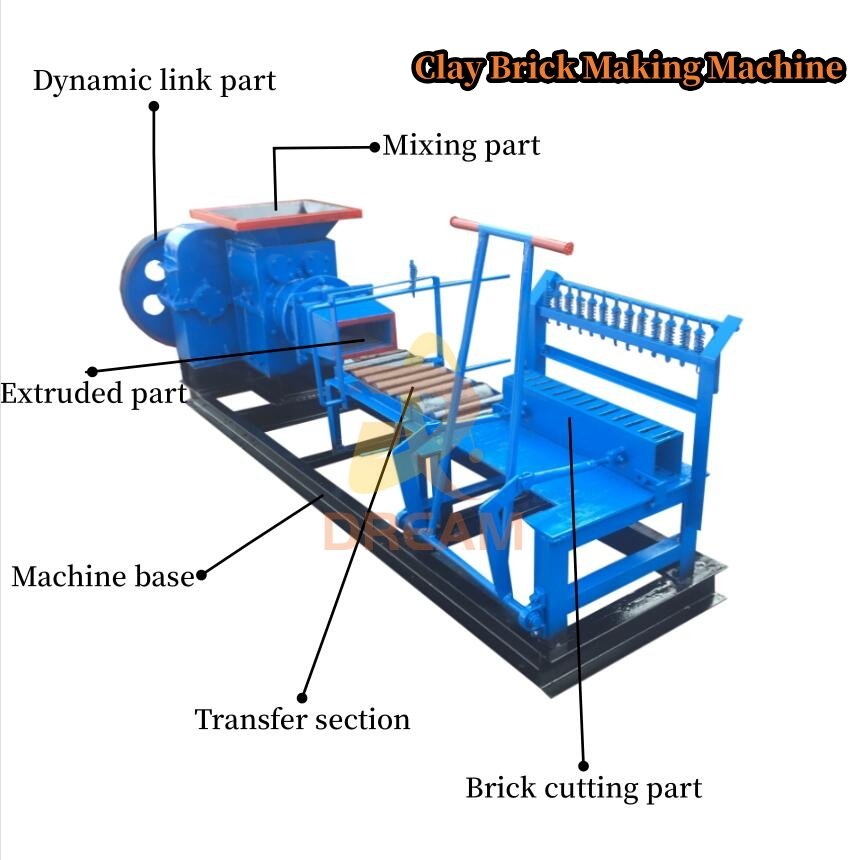

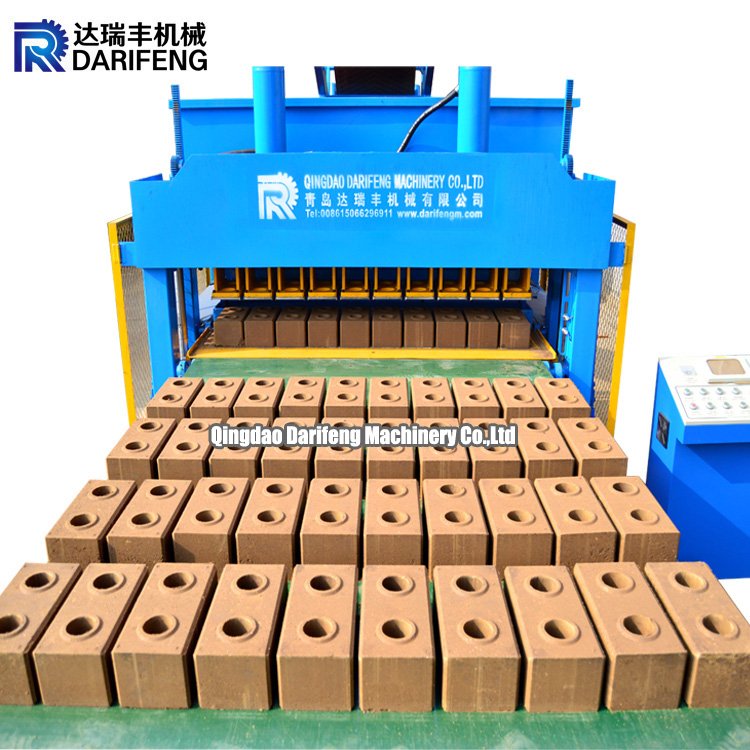

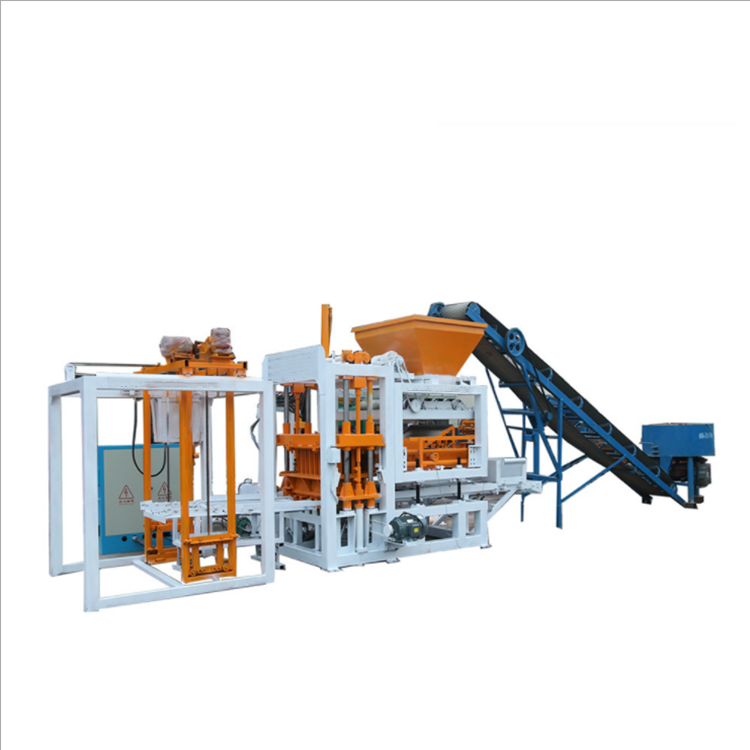

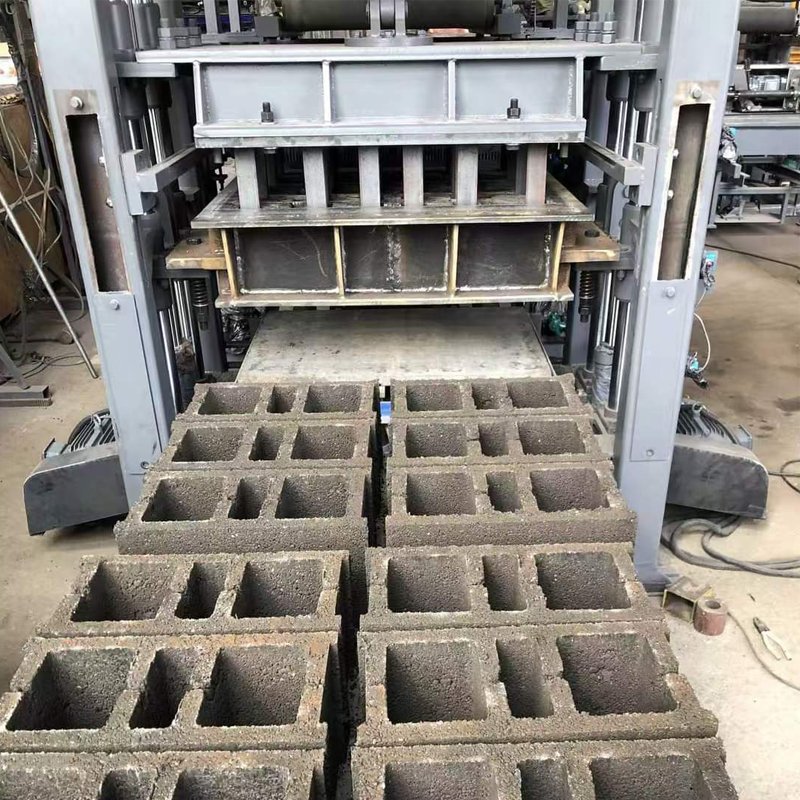

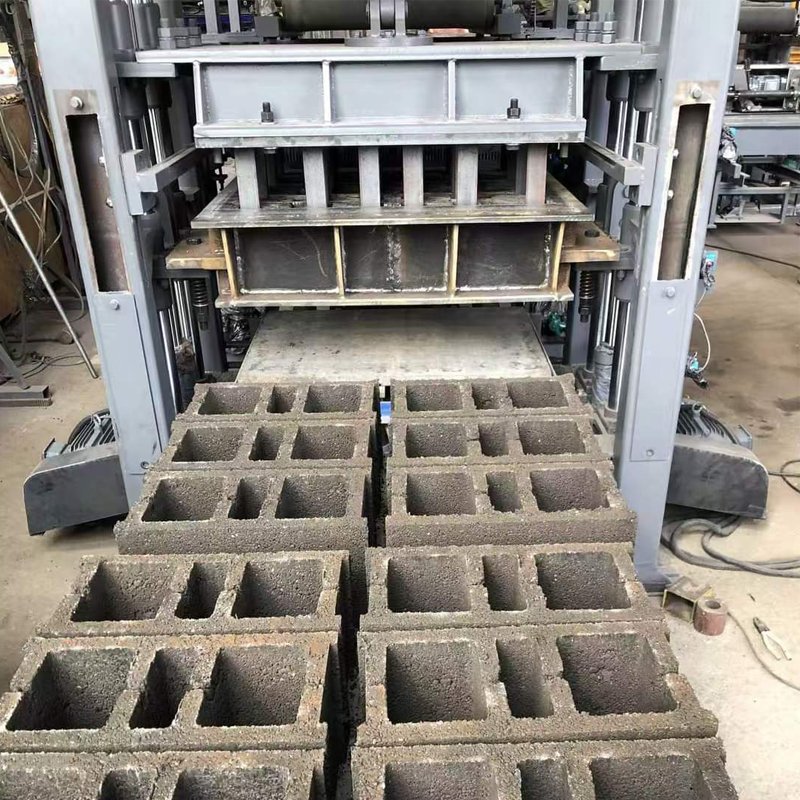

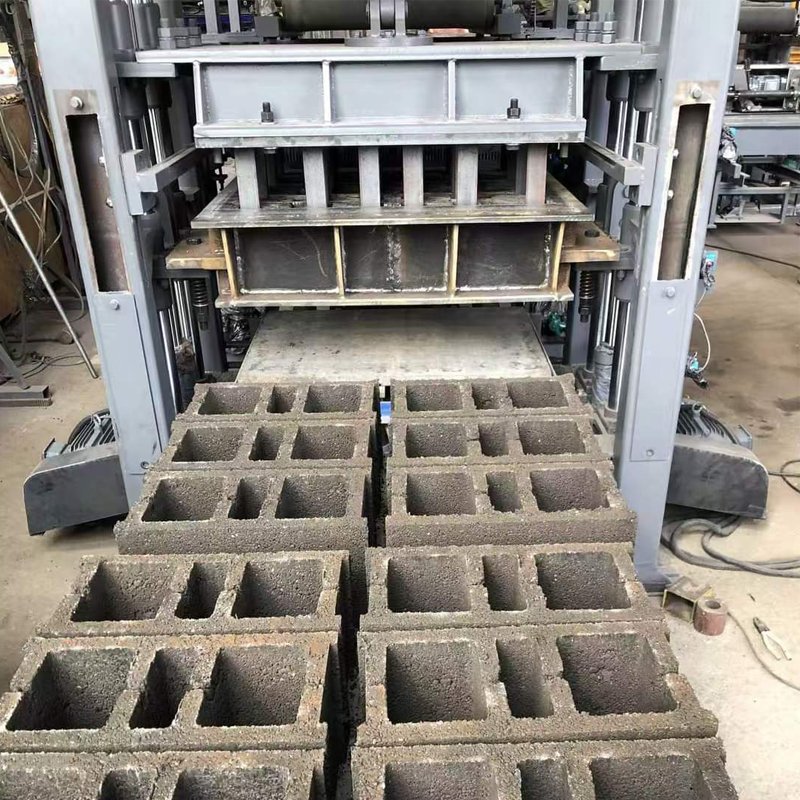

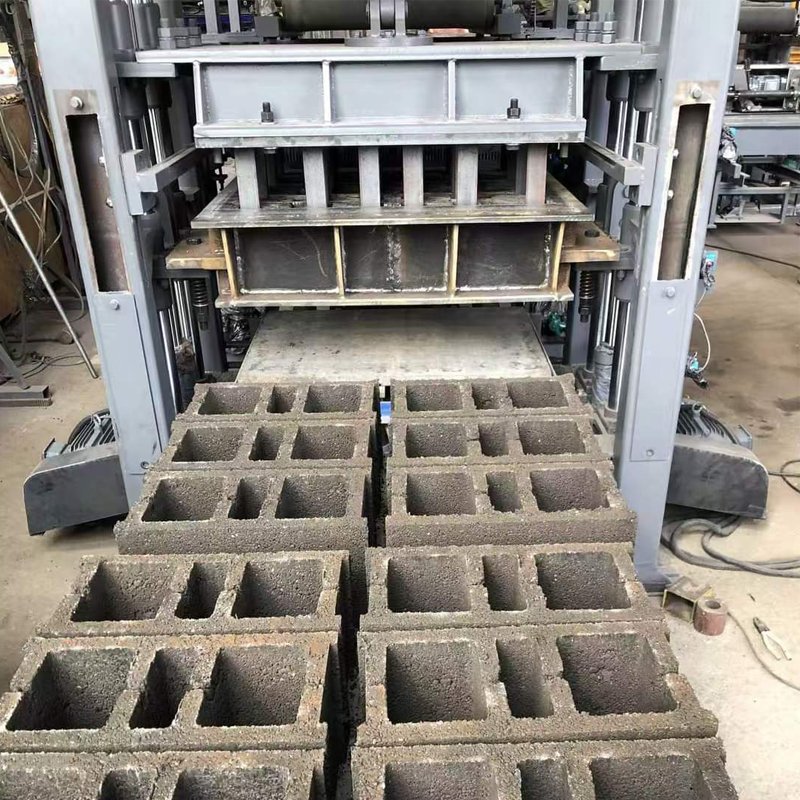

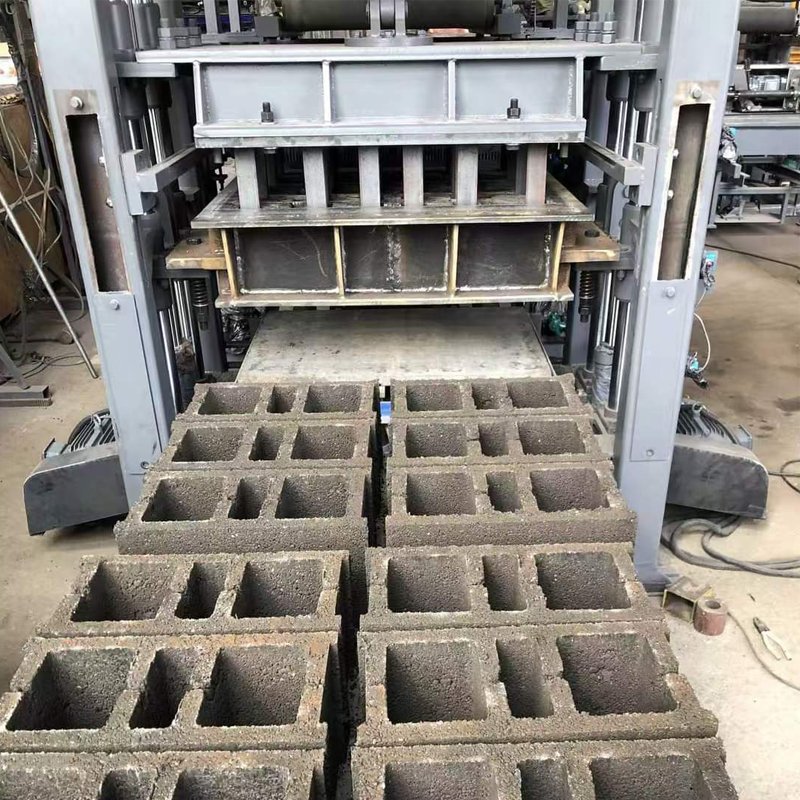

automatic hollow block making machine interlocking cement brick making machinery

$44000$59397.17-25.92%

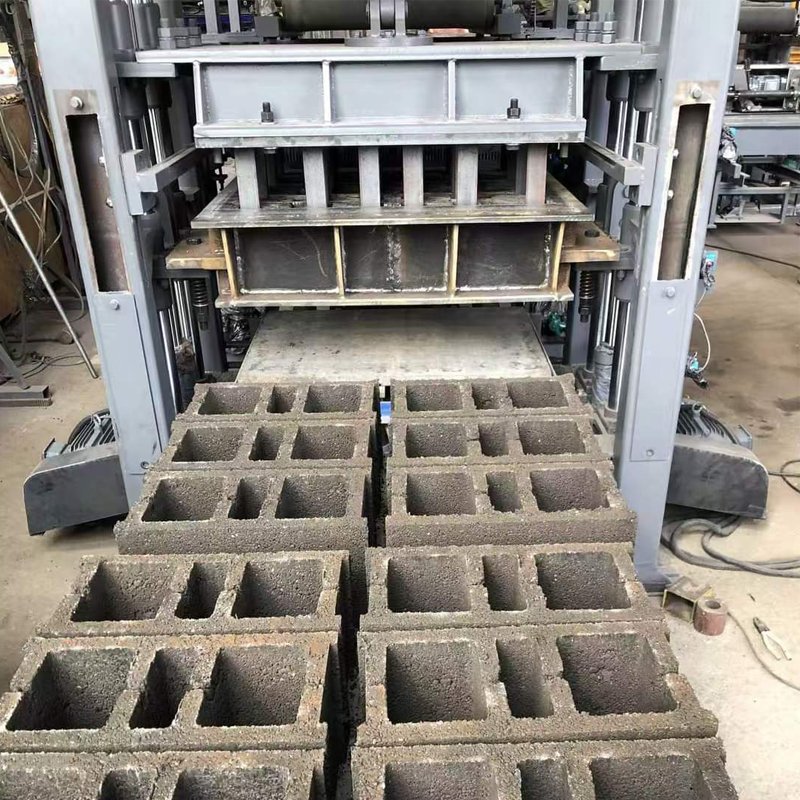

Production Capacity (Pieces/8 hours):

8hours; 5760 pcs

8hours; Other

4480 pcs

Quantity:

Add to Cart

Wishlist

Features

Automatic Hollow Block Making Machine – Interlocking Cement Brick Machinery

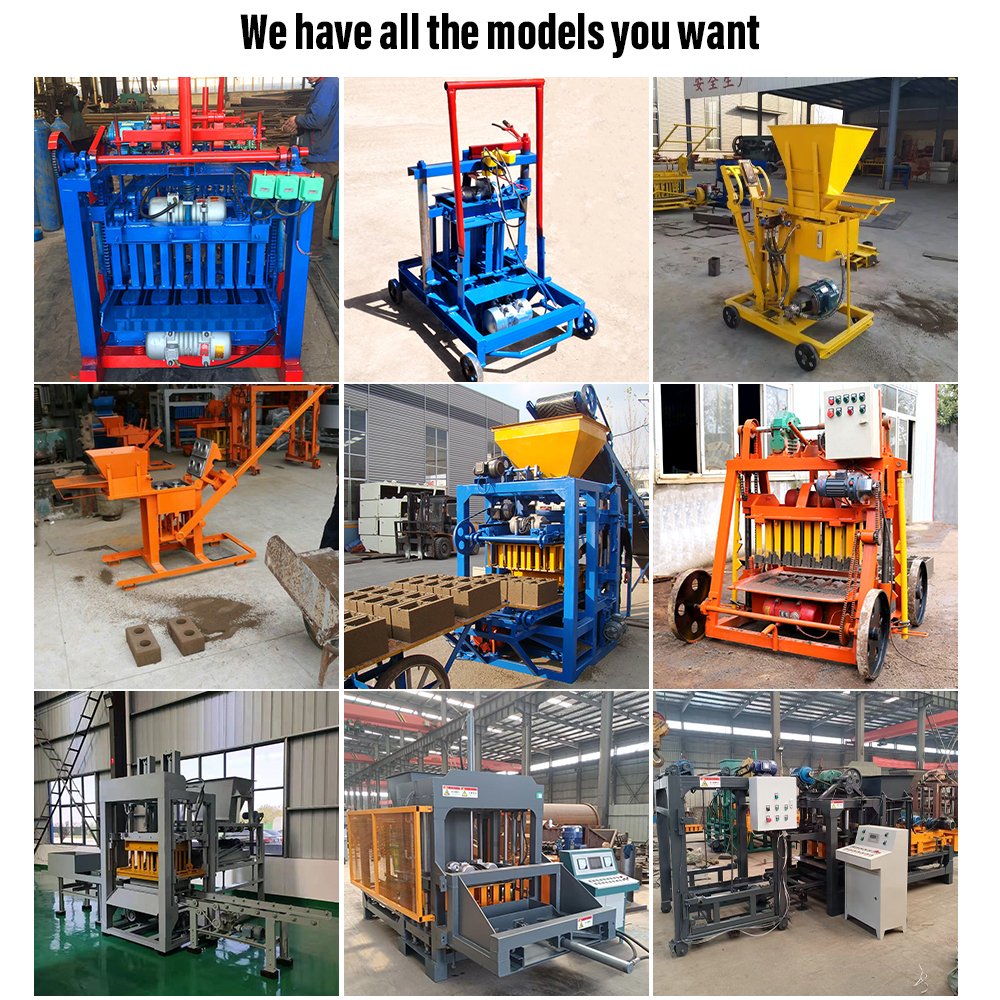

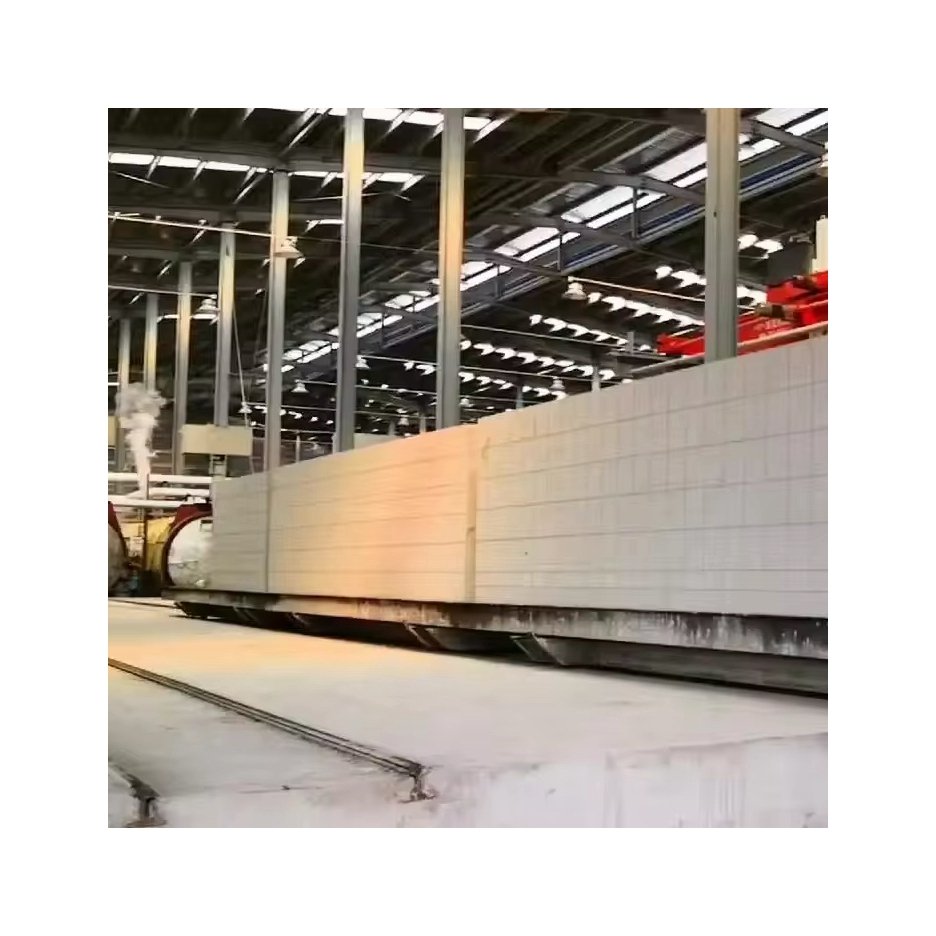

Durable heavy-duty steel frame with precision welding ensures long-lasting stability under high-pressure operation. Advanced hydraulic system delivers consistent 350-ton compression for uniform brick density. Interlocking mold design creates seamless brick alignment, ideal for eco-friendly construction projects. Customizable brick dimensions (standard 400x200x150mm) adapt to diverse architectural needs. Fully automated PLC control panel enables one-touch operation, reducing labor costs by 60%. Integrated vibration motor (1.5kW) enhances mixture compaction for crack-resistant bricks. Energy-efficient 7.5kW motor cuts production costs while outputting 1,200 bricks/hour. Includes built-in safety sensors to prevent overload damage during continuous operation. Perfect for mass-producing pavers, retaining walls, and low-cost housing developments. Includes free technical schematics and 24-month warranty on core components. *Note: Compatible with cement, fly ash, or slag mixtures (6:3:1 ratio recommended).*

See More