Recent Purchase

View All

Customer Reviews

Average Rating

5.0

5.0

2 global ratings

5 star

100%

4 star

0%

3 star

0%

2 star

0%

1 star

0%

All Reviews

Image

Recommend

Recent

u***8

Helpful (2)

I got everything I ordered and everything fit so good.

Feb.12.2025

Helpful (2)

Feb.12.2025

u***3

Helpful (2)

Fast delivery, great product just like picture

Jan.14.2025

Helpful (2)

Jan.14.2025

- 1

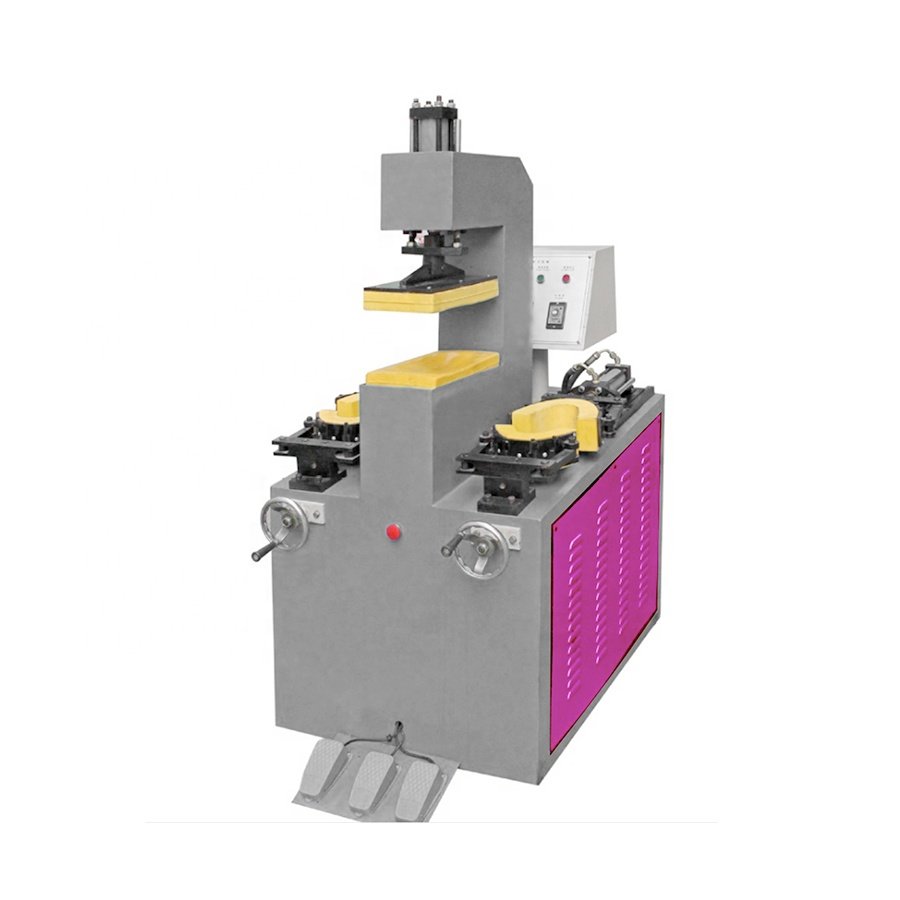

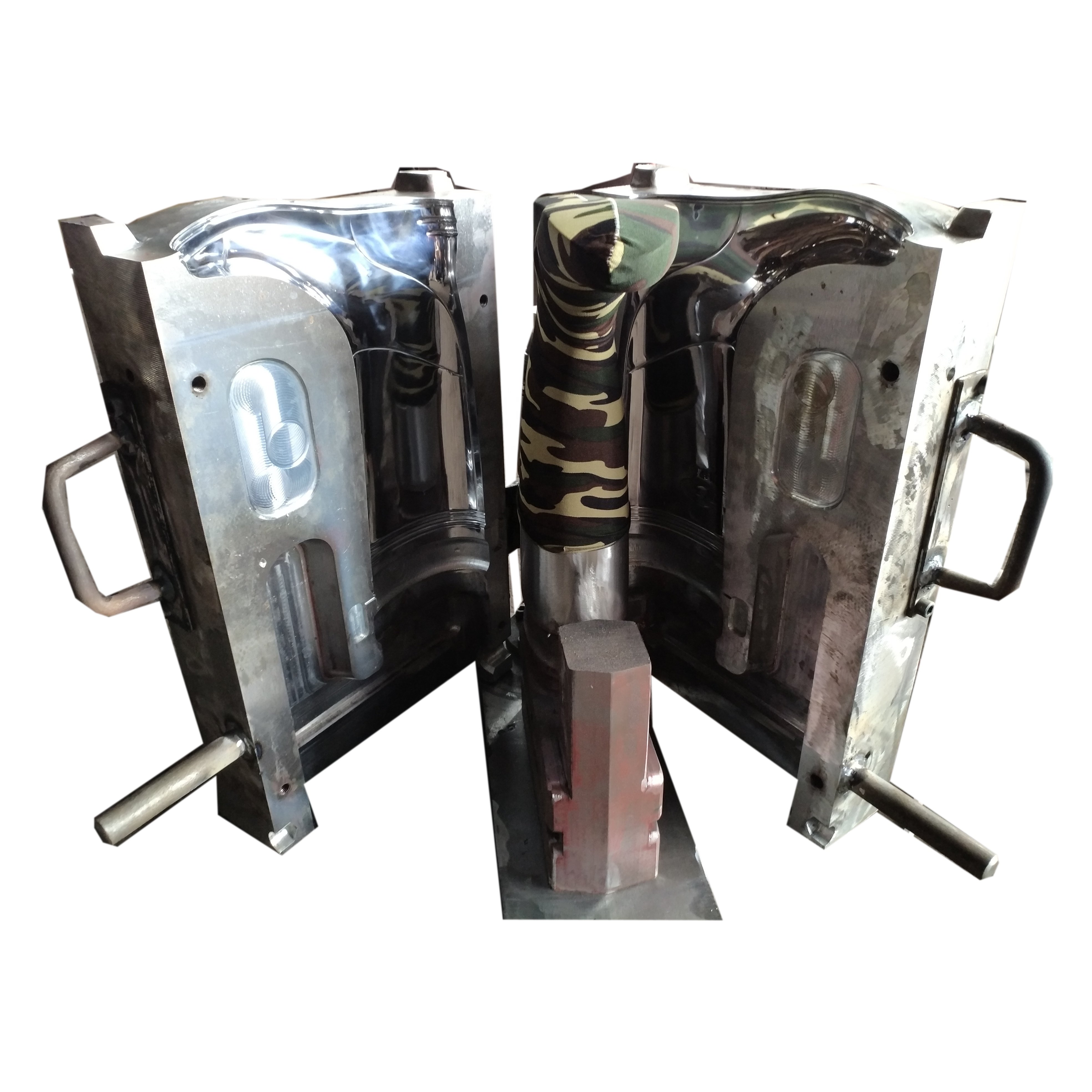

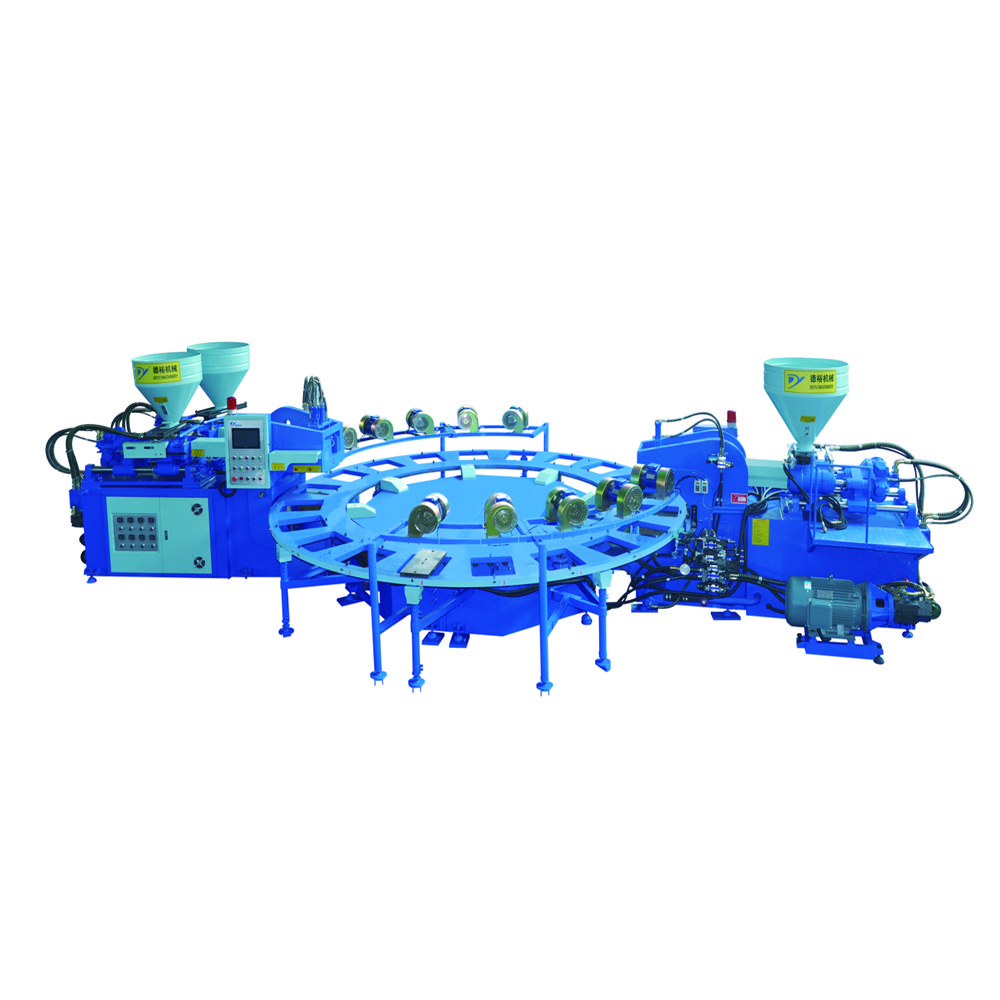

2000BPH Semi Automatic Plastic PET Bottle Making Machine 4 Cavities Bottle Blow Molding Machine

$8500$11284.86-24.68%

Bottle Volume (ml):

200-1500ml

Production Capacity (BPH):

800

500

600

1000

700

900

1100

Quantity:

Add to Cart

Wishlist

Features

Key Features of 2000BPH Semi-Automatic PET Bottle Making Machine

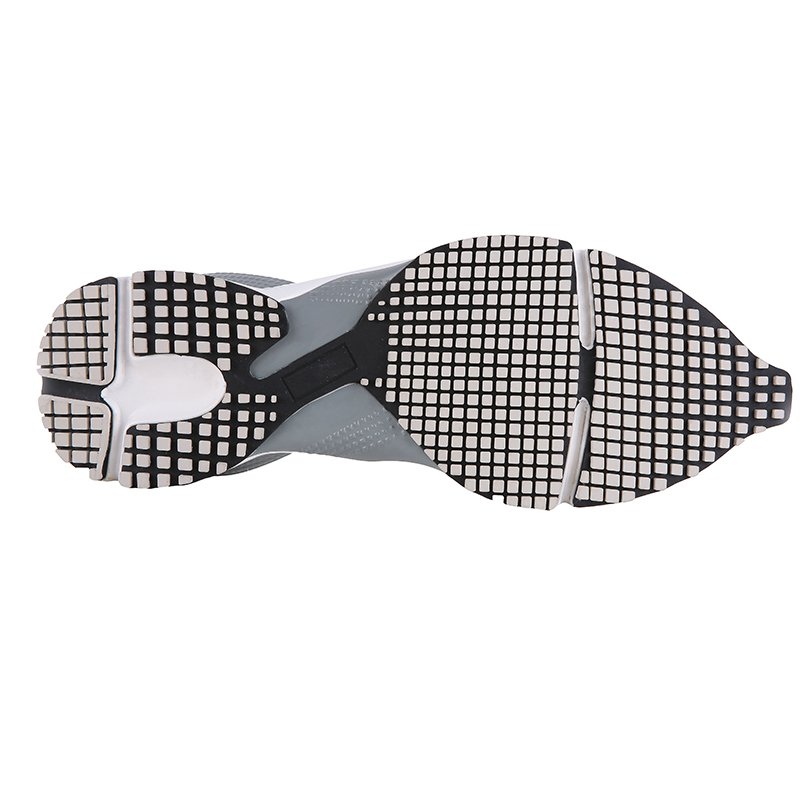

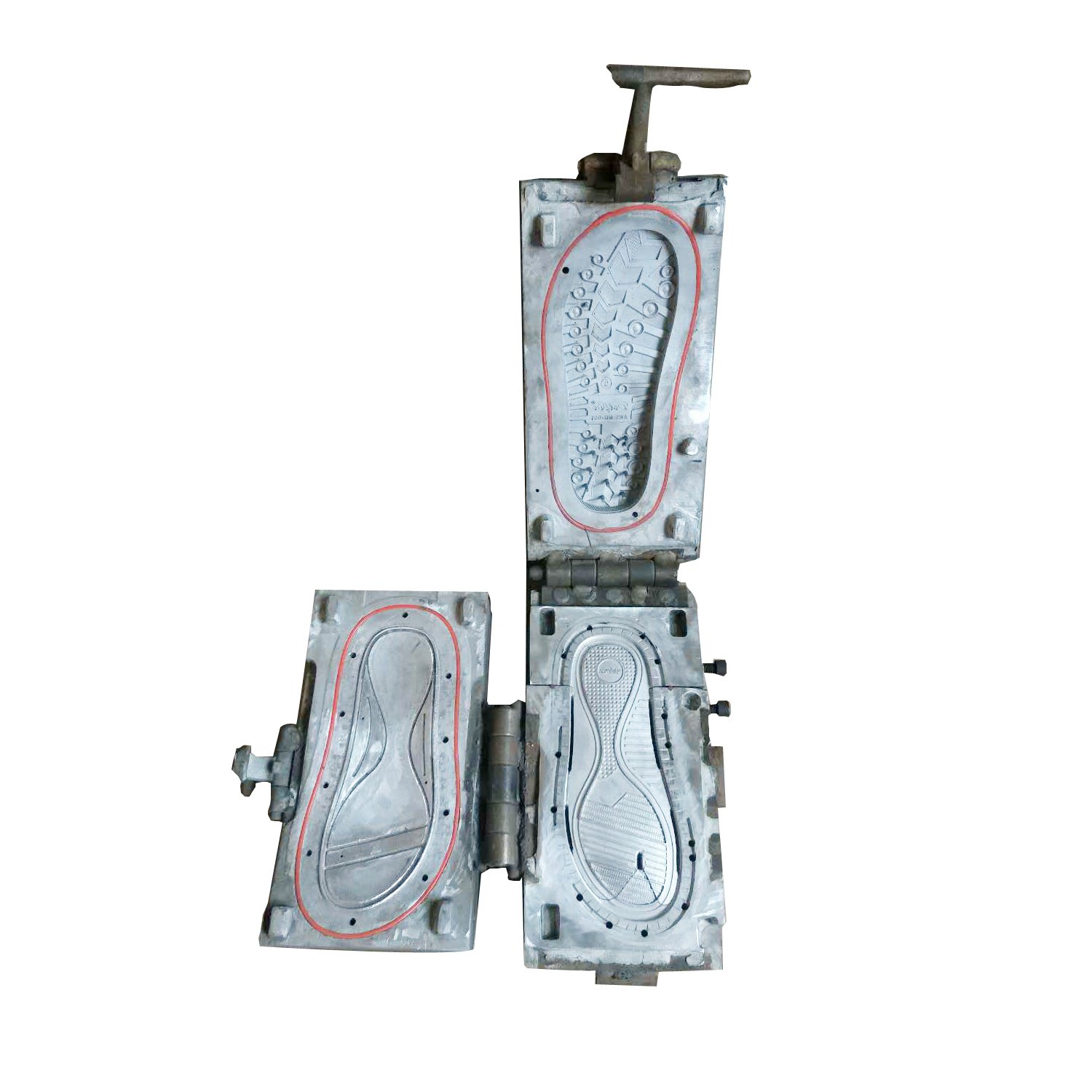

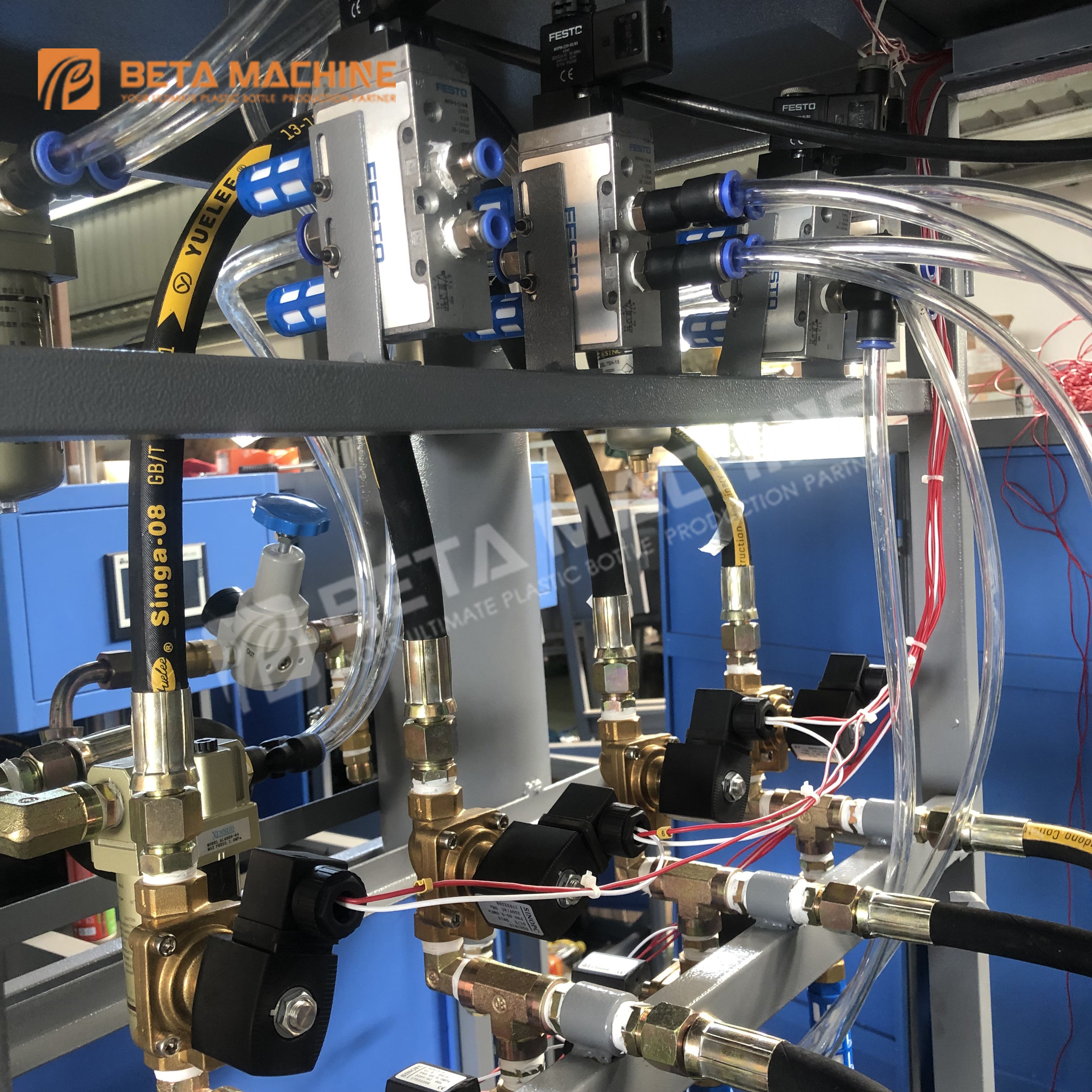

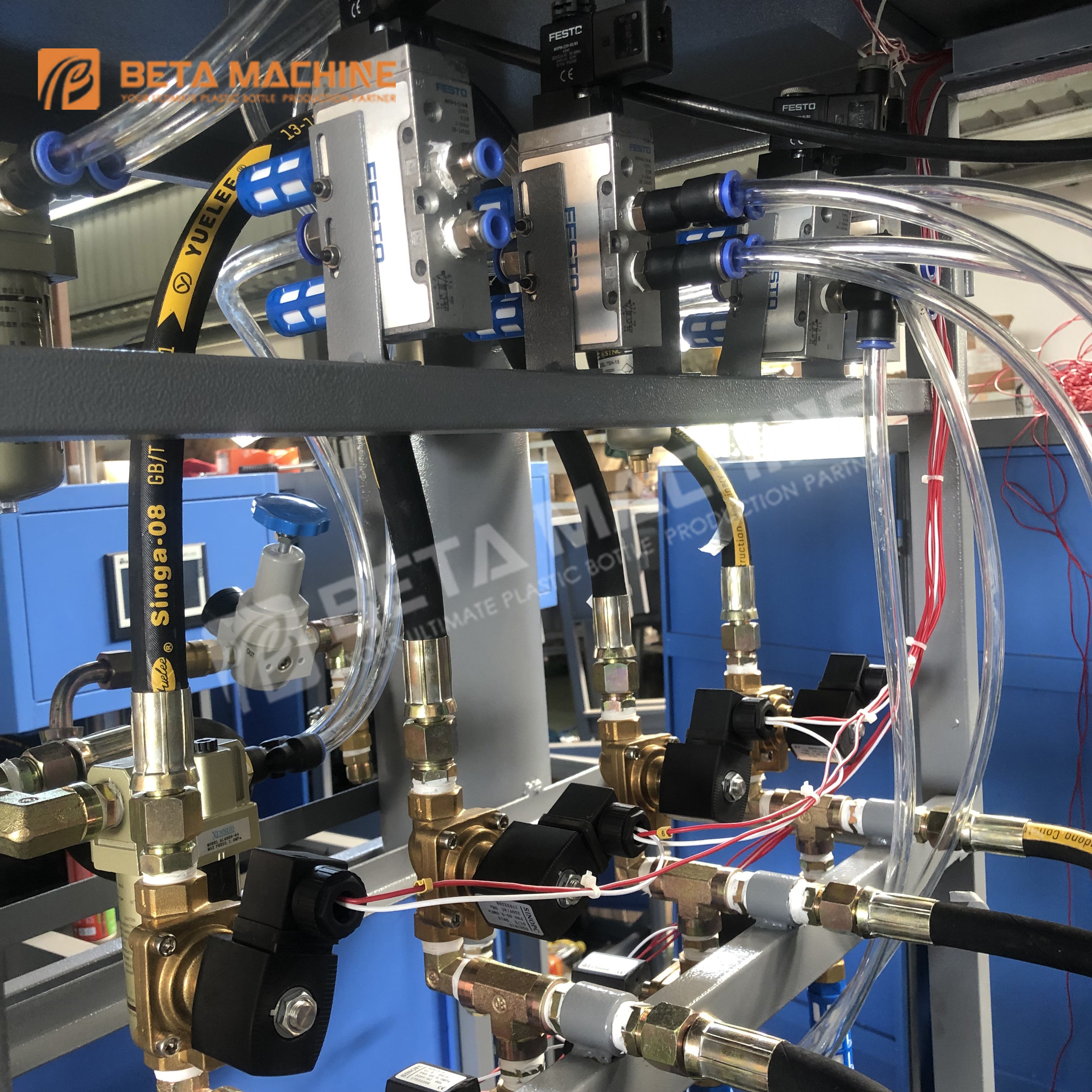

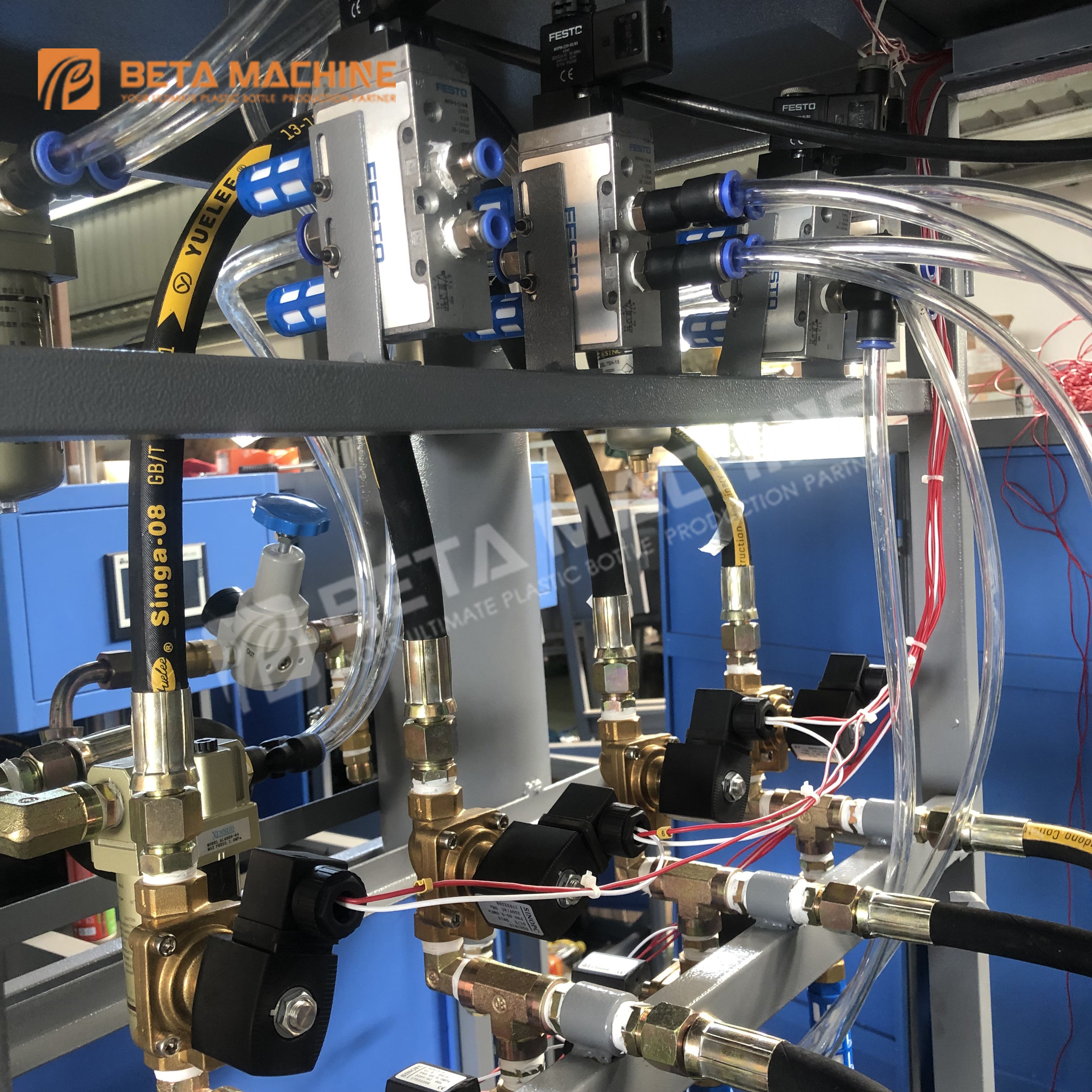

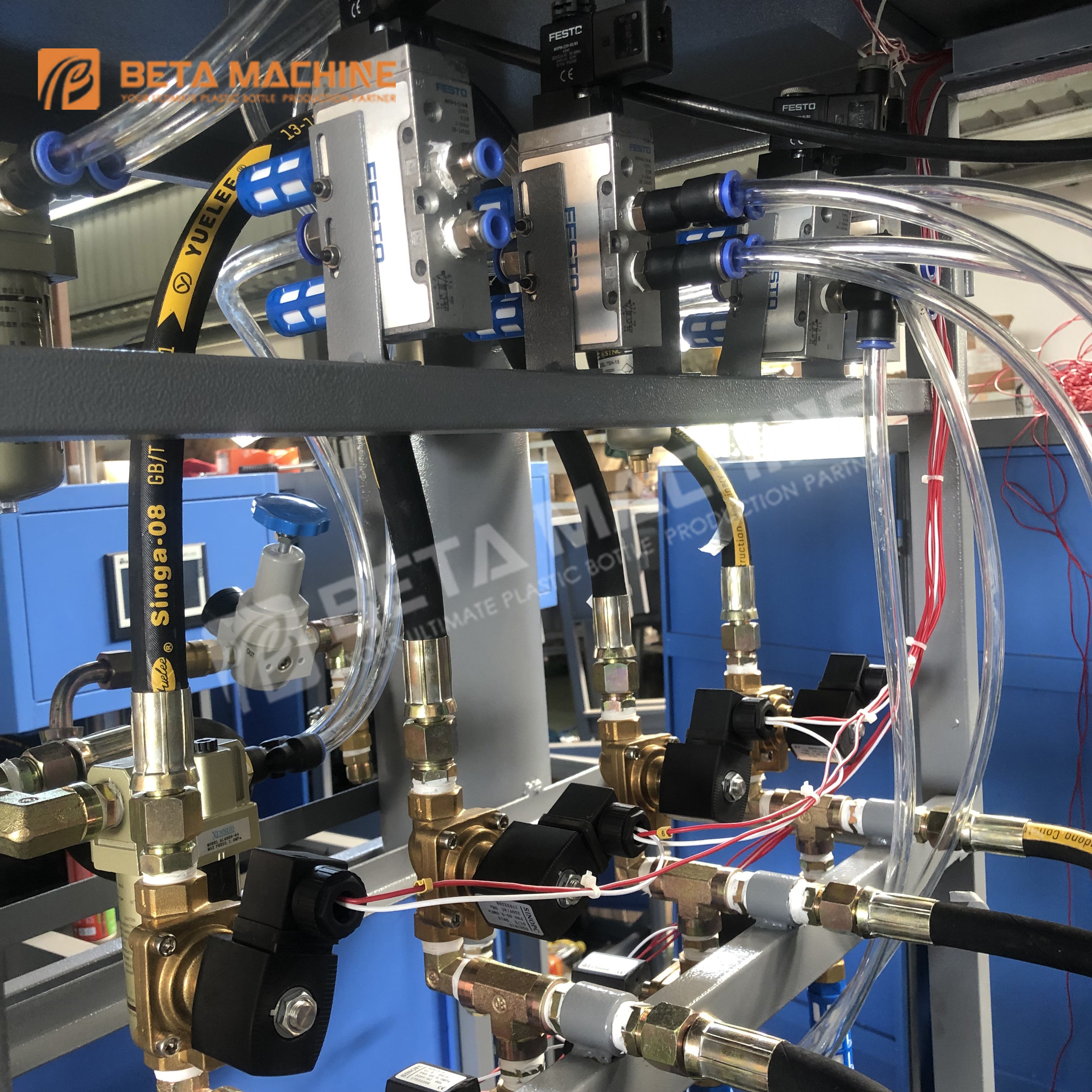

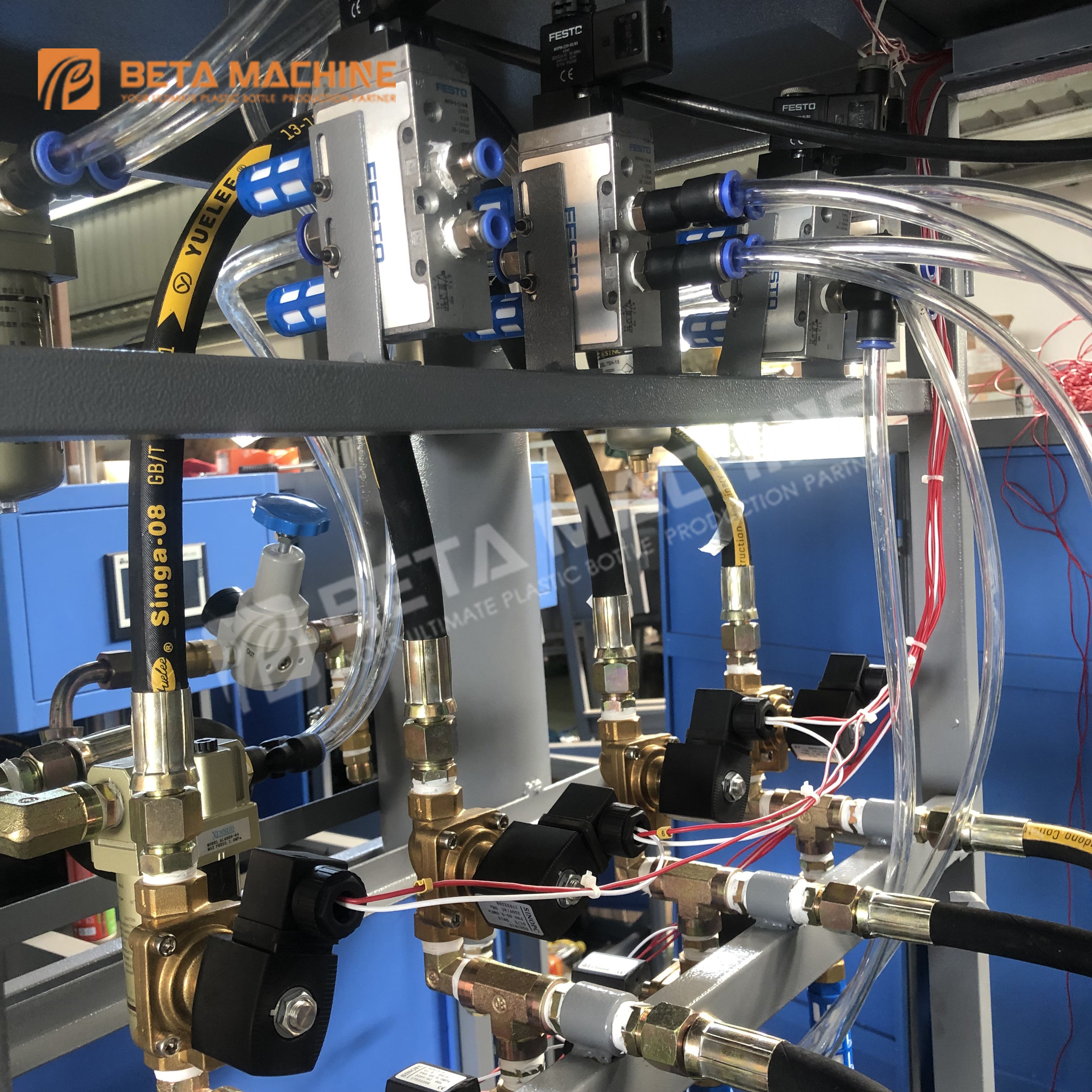

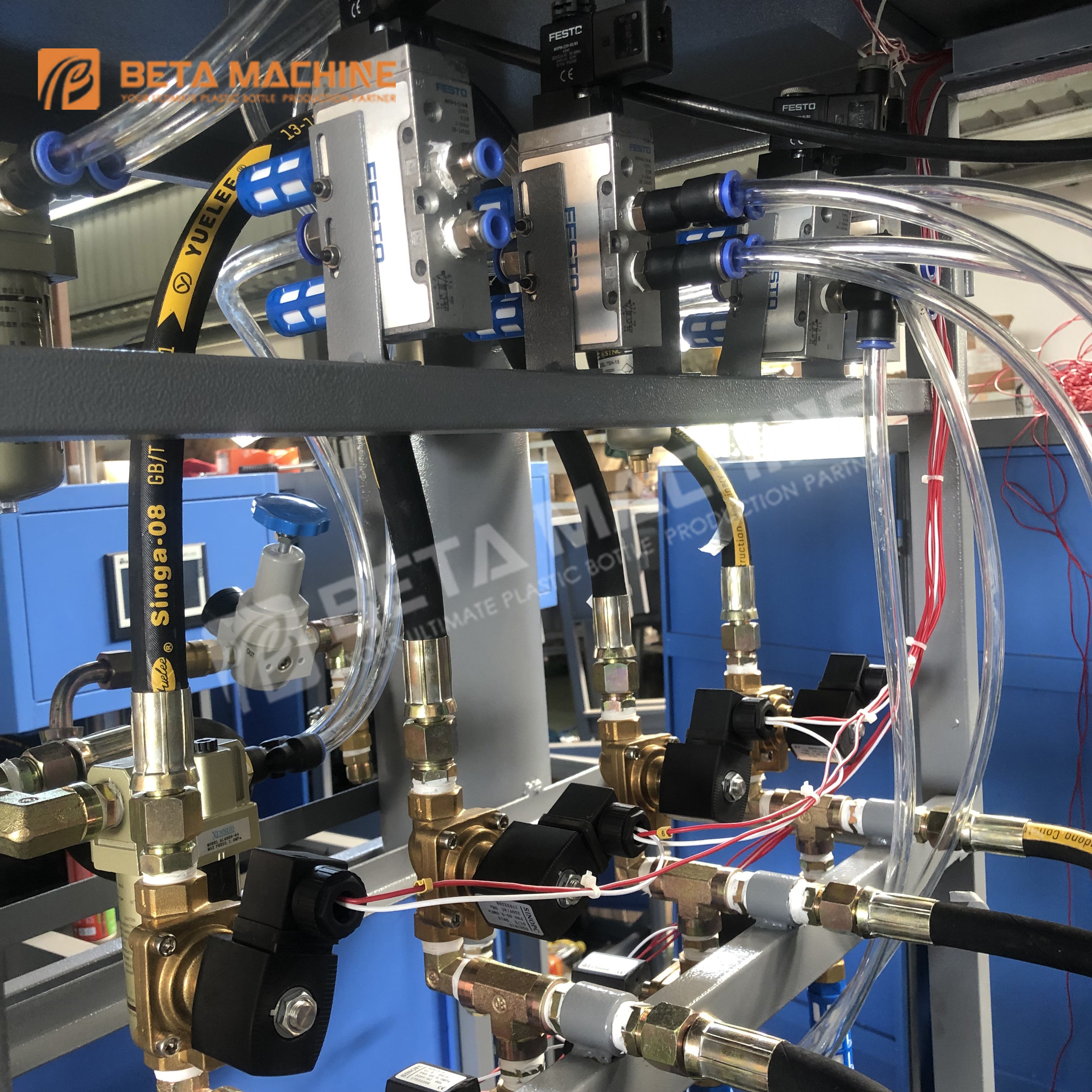

High-efficiency production with 2000 bottles per hour capacity, ideal for medium-scale beverage, cosmetic, and pharmaceutical packaging. Features 4-cavity mold design for consistent output, reducing cycle time while maintaining precision in bottle shape and thickness. Constructed with heavy-duty stainless steel frame and durable pneumatic components for long-lasting performance in humid or high-temperature environments. Semi-automatic operation balances productivity and cost, suitable for startups or expanding businesses needing reliable, low-maintenance equipment. Advanced PLC control system ensures easy adjustment of blow pressure, temperature, and timing for versatile PET bottle designs (0.1L-2L). Energy-saving infrared heating system evenly distributes heat, minimizing material waste and optimizing preform melting. Common applications: carbonated drinks, mineral water, edible oil, and detergent bottles with neck finishes from 18mm to 38mm. Tool-free mold changeover simplifies switching between bottle designs, reducing downtime. Includes safety door locks and emergency stop function, compliant with CE electrical standards. Compact footprint (2.8m x 1.5m) fits small workshops; operates on standard 220V/380V power. Supplied with basic spare parts (nozzles, air filters) and illustrated English manual for quick setup.

Note:

Compatible with PET preforms only; recommend pairing with our bulk preform inventory for seamless supply chain.

See More