Recent Purchase

View All

Customer Reviews

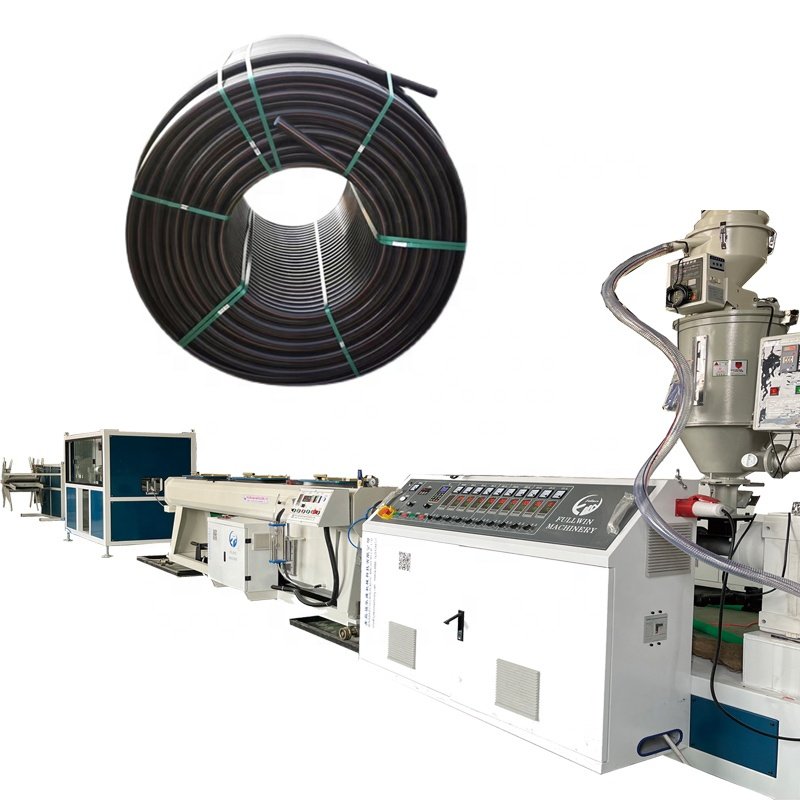

plastic PP PE PVC EVA PA Single wall corrugated shisha hookah magic water hoses manufacture machine line equipment

$56000$75382.39-25.71%

Output (kg/h):

hr

50-100kg

Quantity:

Add to Cart

Wishlist

Features

High-Quality PP PE PVC EVA PA Single-Wall Corrugated Hookah Hose Manufacturing Machine

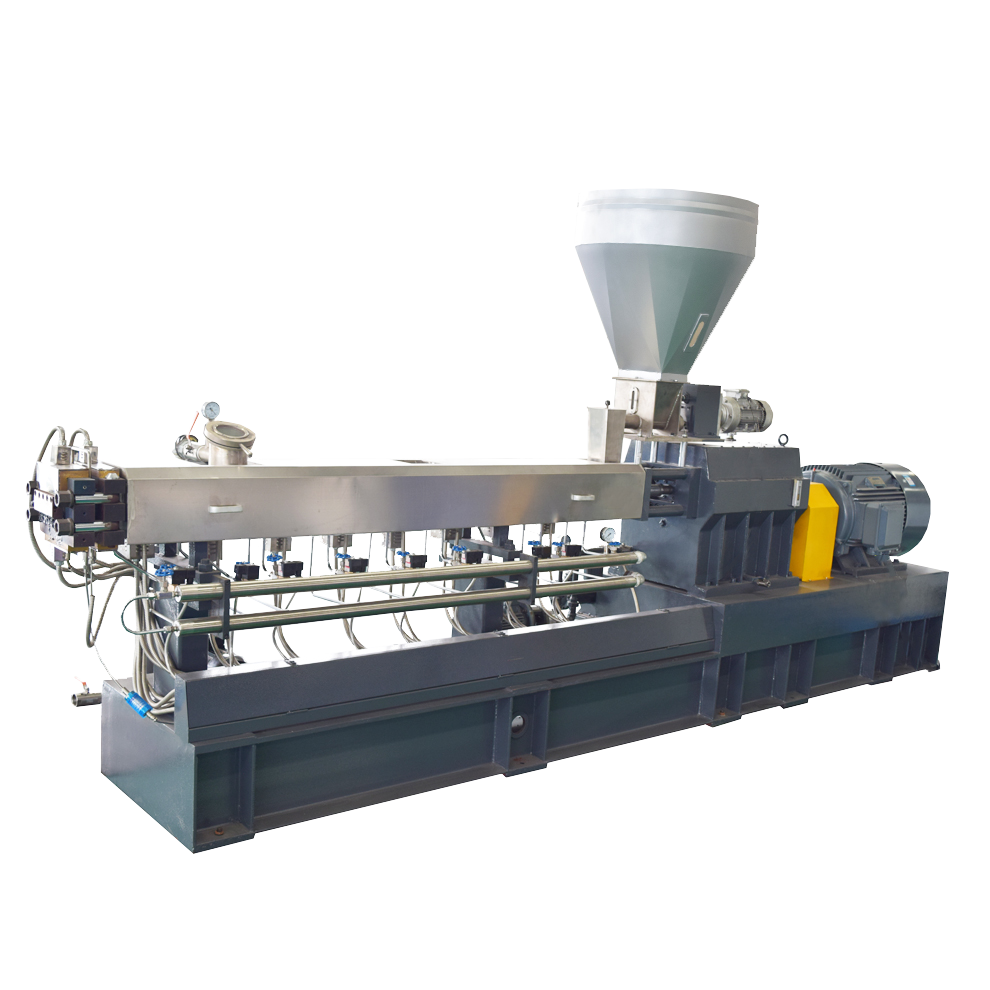

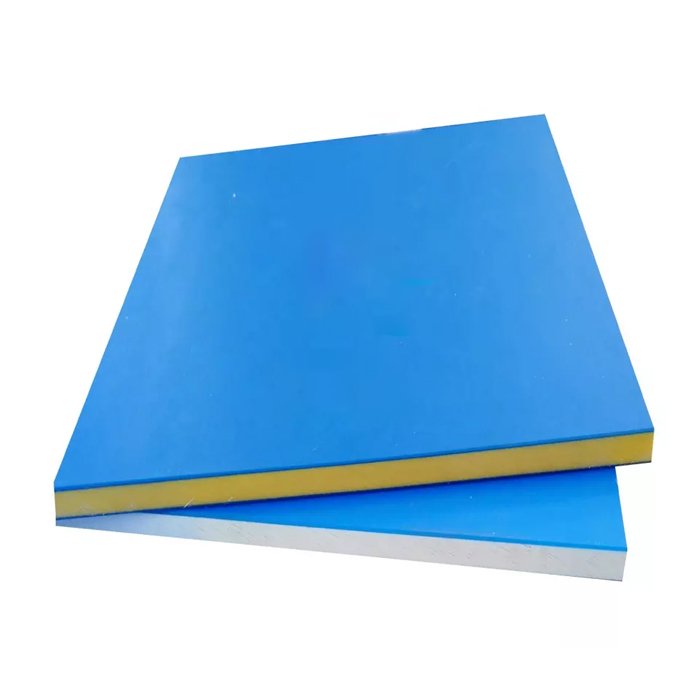

Premium Material Construction

– Engineered with high-grade PP, PE, PVC, EVA, and PA for superior durability, flexibility, and chemical resistance, ensuring long-lasting performance.

Precision Manufacturing

– Advanced extrusion and corrugation technology guarantees consistent wall thickness, smooth airflow, and leak-proof design for optimal hookah hose functionality.

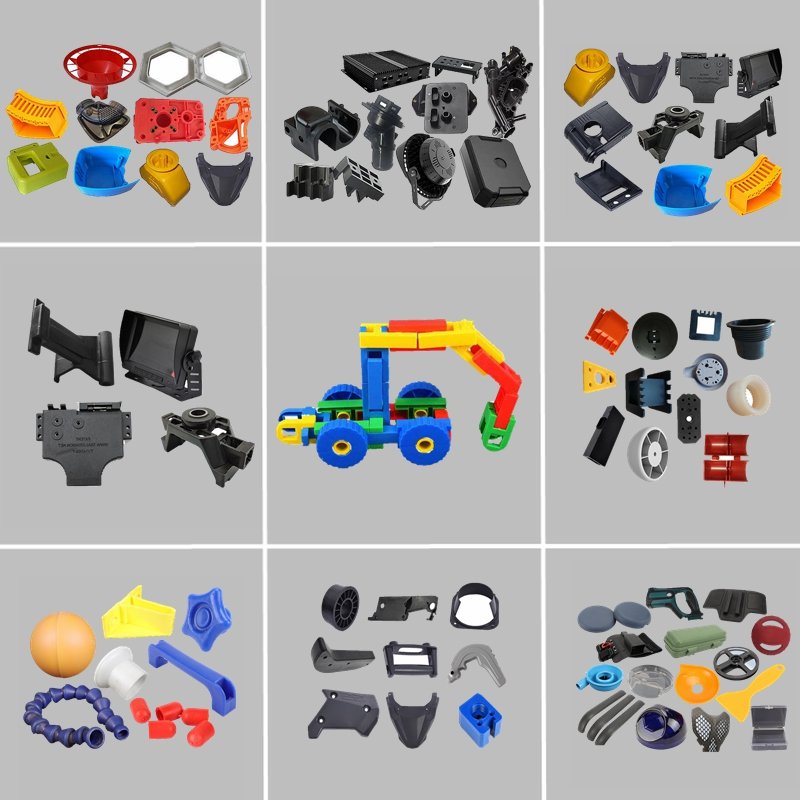

Versatile Applications

– Ideal for producing shisha, hookah, and magic water hoses, catering to both commercial manufacturers and DIY enthusiasts seeking custom hose solutions.

Efficient Production Line

– Fully automated equipment ensures high output with minimal waste, perfect for bulk orders and wholesale suppliers looking to scale production.

Global Wholesale Advantage

– Direct factory pricing with no middlemen, offering unbeatable rates for large-volume buyers sourcing premium hookah accessories worldwide.

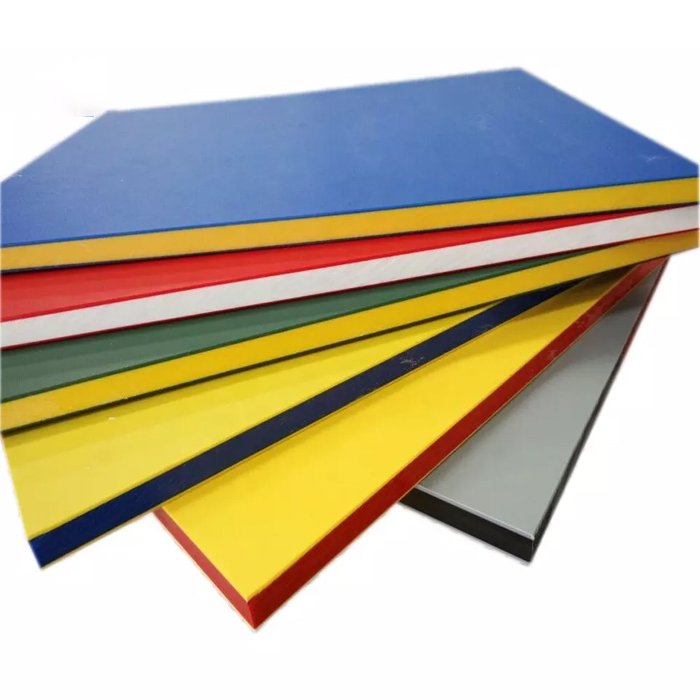

Customization Ready

– Compatible with various polymer blends and adjustable corrugation patterns to meet diverse market demands and branding requirements.

Low Maintenance Design

– Robust machinery built for continuous operation, reducing downtime and maximizing productivity for industrial-scale manufacturing.

Wide Material Compatibility

– Processes multiple thermoplastics, allowing flexibility in hose texture, hardness, and color to match specific customer preferences.

End-to-End Solution

– From raw material feeding to finished hose cutting, the integrated system streamlines production for hassle-free, high-quality output.

See More