Recent Purchase

View All

Customer Reviews

Average Rating

4.5

4.5

2 global ratings

5 star

50%

4 star

50%

3 star

0%

2 star

0%

1 star

0%

All Reviews

Image

Recommend

Recent

u***1

Helpful (1)

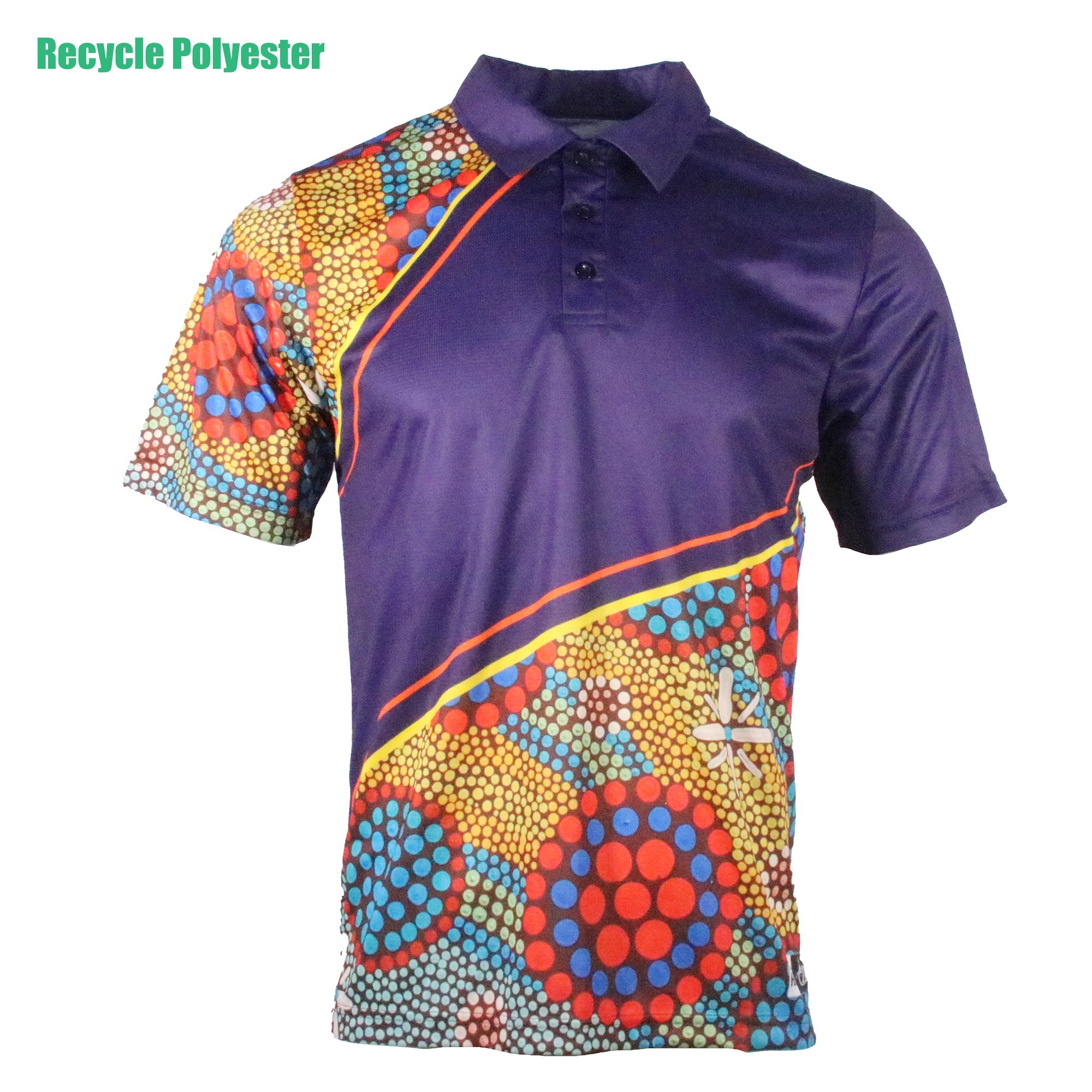

I love this app ,the clothes are so cute ,and the delivery is always on time …

Jun.14.2024

Helpful (1)

Jun.14.2024

u***8

Helpful (1)

Me encanta todo mis pedidos han llegado a tiempo y de muy buena calidad

Aug.05.2024

Helpful (1)

Aug.05.2024

- 1

injection molding machinery eps/rock wool foam sandwich pan el machines

$100000$126612.45-21.02%

Model Number:

TYF sandwich panel machine

Power:

32 kw

Quantity:

Add to Cart

Wishlist

Features

High-Precision Injection Molding Machinery for EPS/Rock Wool Foam Sandwich Panels

Industrial-Grade Performance

– Heavy-duty steel construction with advanced hydraulic systems ensures durability and long-term reliability for high-volume production.

Versatile Material Compatibility

– Processes EPS (Expanded Polystyrene) and rock wool foam seamlessly, creating ultra-lightweight yet rigid sandwich panels with superior thermal insulation.

Energy-Efficient Design

– Optimized motor and heating elements reduce power consumption by up to 20% without compromising output speed or molding accuracy.

Pinpoint Temperature Control

– Digital thermostats maintain ±1°C precision for consistent foam expansion and panel density, critical for construction and cold storage applications.

Quick-Mold Change System

– Patented clamp mechanism allows mold swaps in under 15 minutes, ideal for factories producing multiple panel thicknesses (50-200mm range).

Automated Production Ready

– Integrated robotic arm compatibility for unattended operation, slashing labor costs in large-scale insulation panel manufacturing.

End-to-End Customization

– Supports tailor-made mold designs for specialized panel profiles, including fluted, smooth, or embossed finishes.

Global Compliance Certified

– CE and ISO 9001 certified with explosion-proof options available for hazardous material handling.

Applications:

- Prefabricated building walls/roofs - Refrigerated truck bodies - Cleanroom partitions - HVAC duct insulation

Why Us:

World’s leading wholesale machinery supplier with direct factory pricing. Ships fully assembled with 24/7 technical support in 12 languages. No middlemen, no hidden costs – pure bulk-order savi

See More