Recent Purchase

View All

Customer Reviews

Average Rating

5.0

5.0

2 global ratings

5 star

100%

4 star

0%

3 star

0%

2 star

0%

1 star

0%

All Reviews

Image

Recommend

Recent

u***2

Helpful (4)

Great products!

Mar.30.2025

Helpful (4)

Mar.30.2025

u***8

Helpful (3)

Fast easy process! Zero hassle! Shopping made easy!

Mar.25.2025

Helpful (3)

Mar.25.2025

- 1

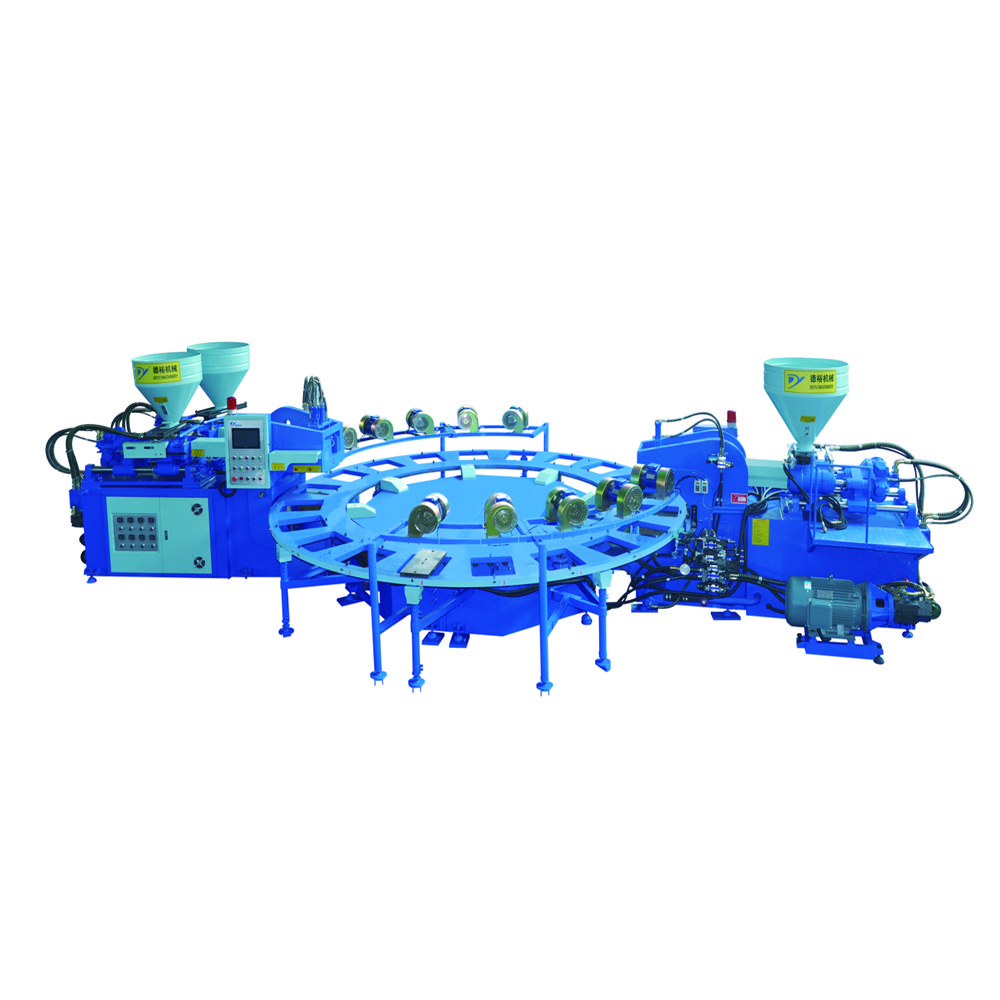

Automatic Rubber Injection Moulding Machine for Making Slipper Sandal Flip-Flop Shoe

$40000$57481.99-30.41%

Model Number:

CGY-500

Quantity:

Add to Cart

Wishlist

Features

Key Features of Automatic Rubber Injection Moulding Machine for Slipper/Sandal Production

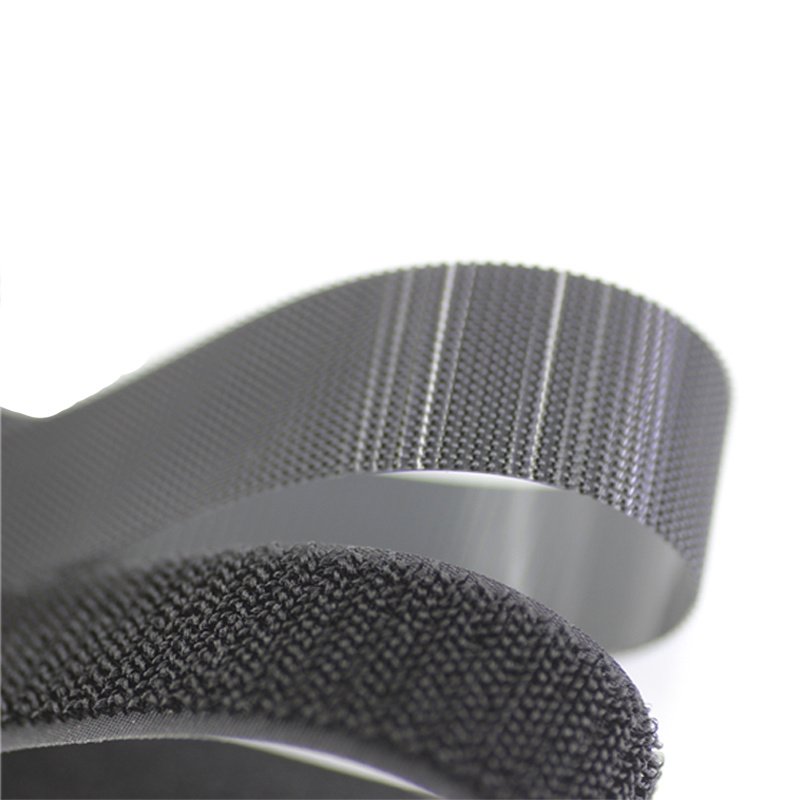

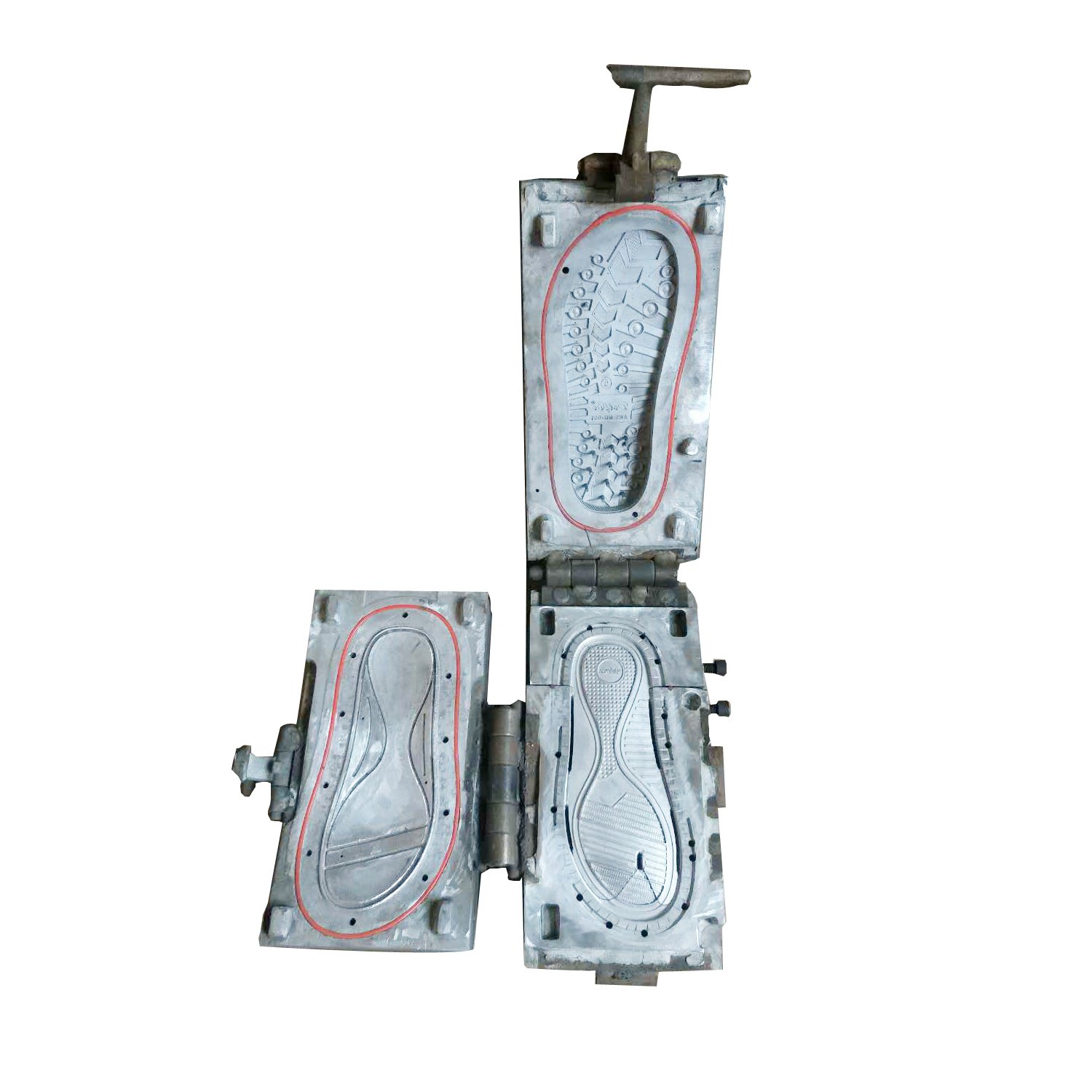

High-precision automatic rubber injection moulding machine designed for mass-producing durable slippers, sandals, and flip-flops with consistent quality. Equipped with advanced PLC control system for seamless operation, reducing labor costs and minimizing human error in high-volume manufacturing. Heavy-duty steel frame with corrosion-resistant coating ensures long-term stability, even under continuous 24/7 production cycles. Customizable mold cavities allow flexible designs, accommodating various shoe sizes (US/EU standards) and sole patterns (anti-slip, textured, or branded logos). Energy-efficient hydraulic system lowers power consumption by 15% compared to conventional models, ideal for cost-sensitive bulk production. Ideal for footwear manufacturers, wholesale exporters, and OEM suppliers targeting supermarkets, beach resorts, and promotional merchandise markets. Includes automatic demolding and trimming functions, reducing post-processing time and enhancing output efficiency (up to 500 pairs per hour). Complies with international safety standards (CE certified), featuring overheating protection and emergency stop mechanisms.

See More