Recent Purchase

View All

Customer Reviews

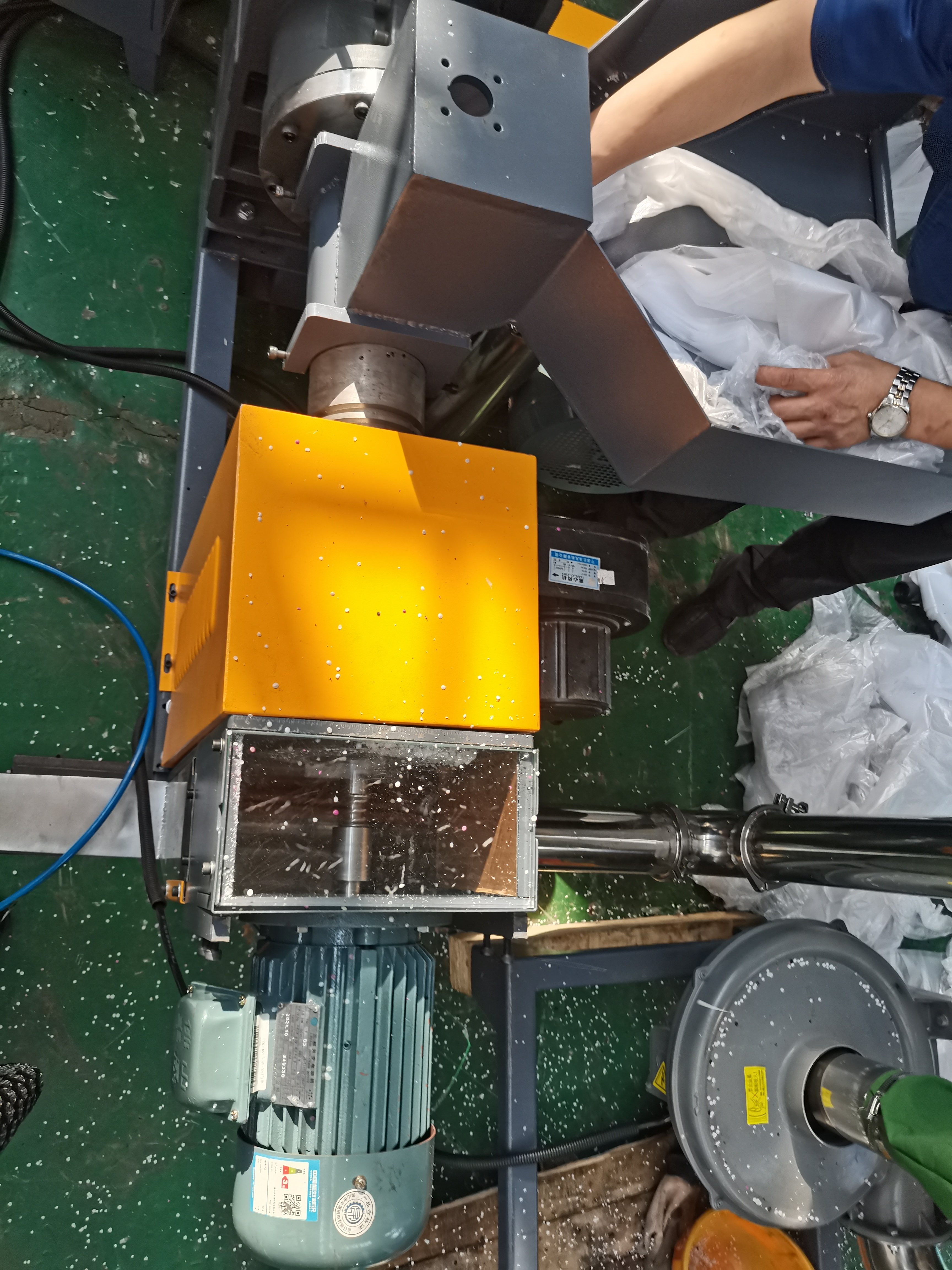

Plastic Pelletizing Machine for Packing film PP PE PET Material Recycling Granules Making Machine

$112000$166208.99-32.61%

Model Number:

ML180 plastic pelletizing machine

ML 85 plastic pelletizing machine

ML100 plastic pelletizing machine

ML160 plastic pelletizing machine

ML130 plastic pelletizing machine

Quantity:

Add to Cart

Wishlist

Features

High-Efficiency Plastic Pelletizing Machine for PP/PE/PET Recycling

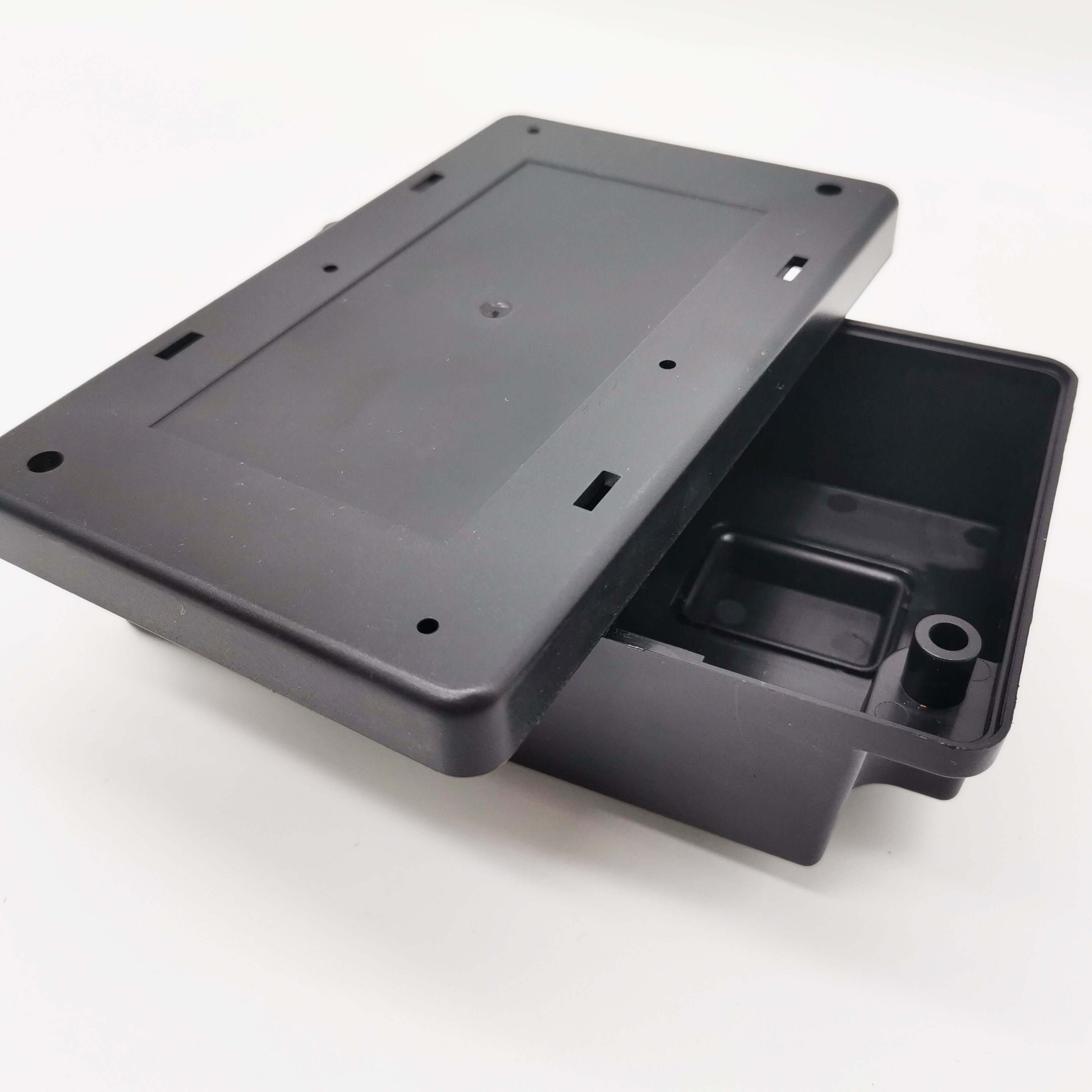

Industrial-Grade Durability

Heavy-duty steel construction with precision-engineered components ensures long-term reliability for continuous operation in demanding environments.

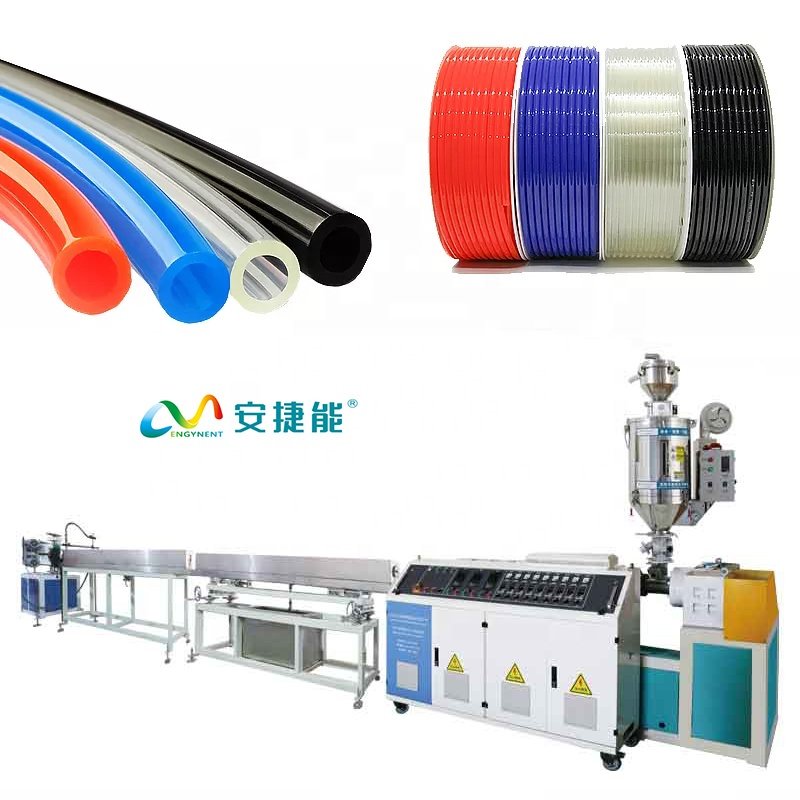

Precision Granulation Technology

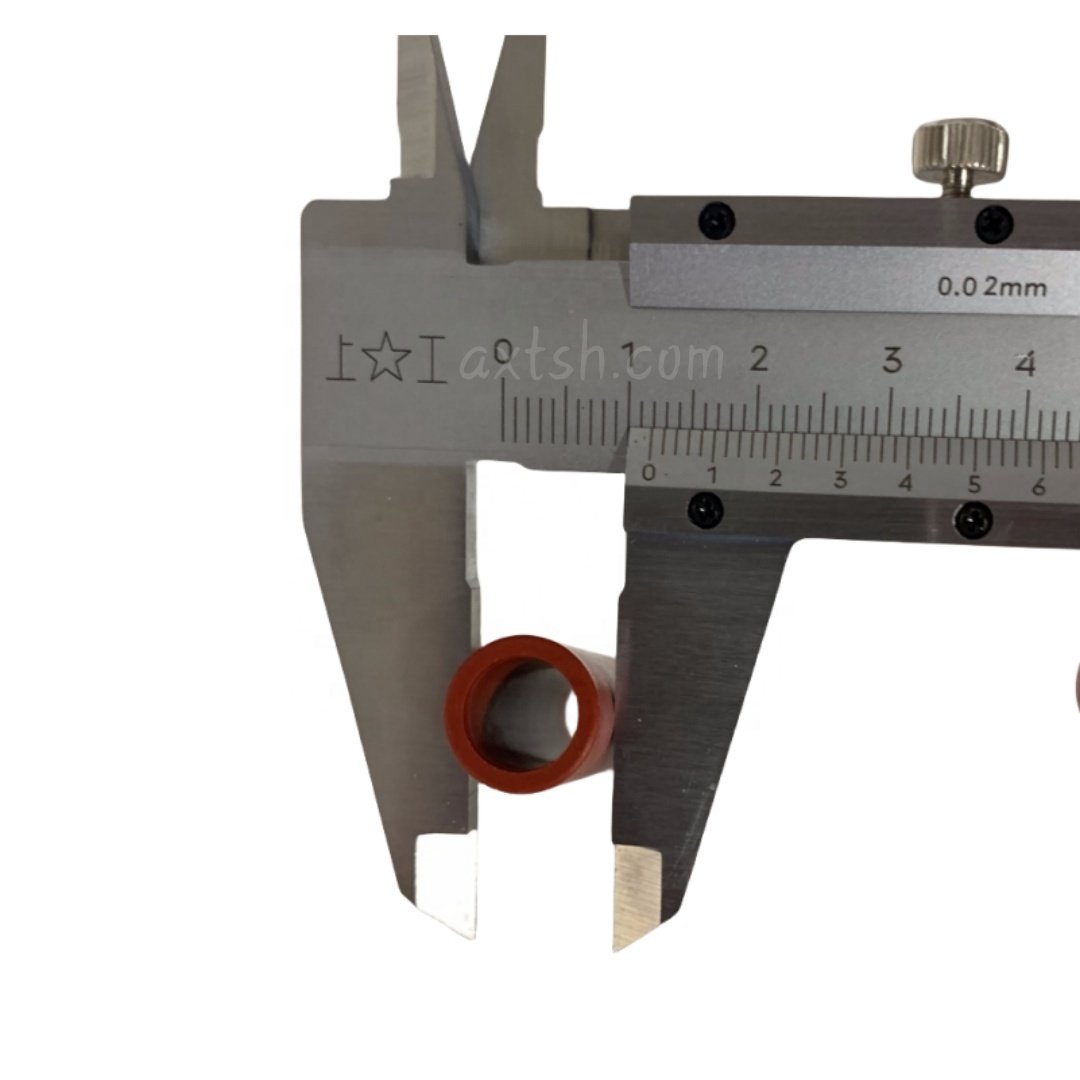

Equipped with advanced cutting blades and optimized screw design for uniform pellet sizing (2-5mm adjustable), minimizing material waste and improving melt consistency.

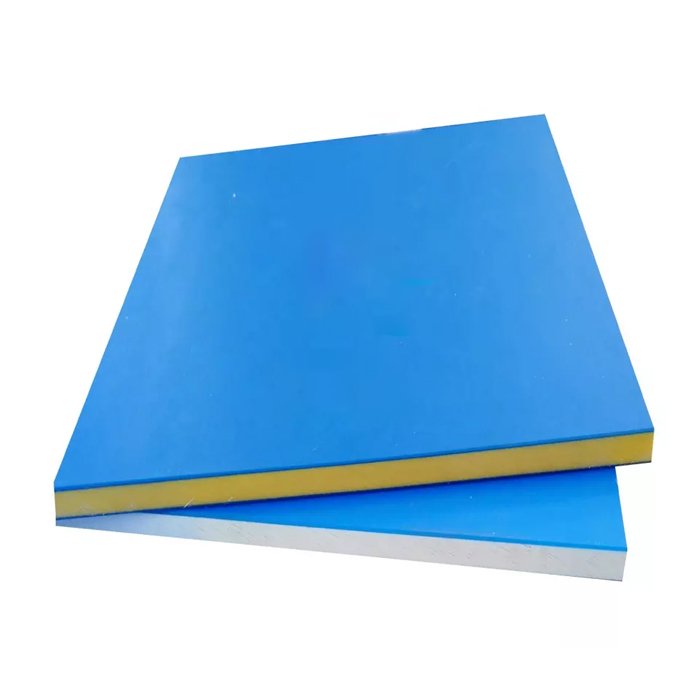

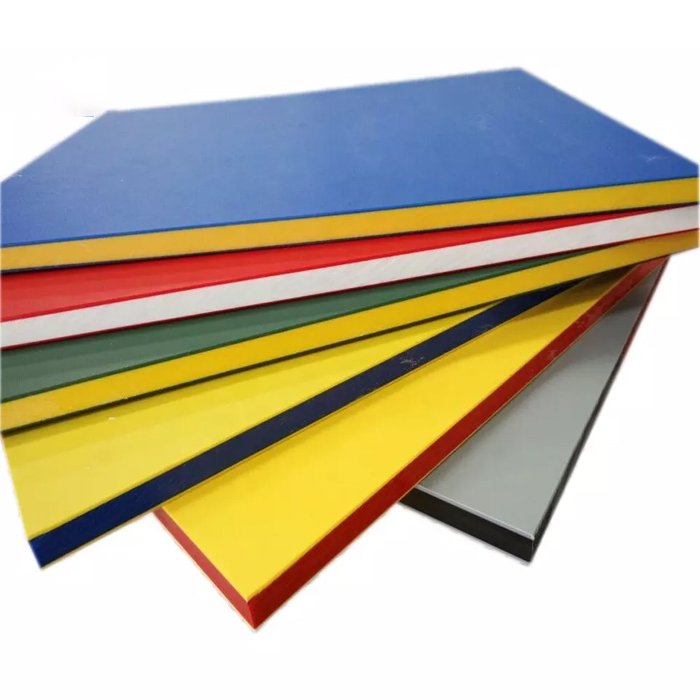

Wide Material Compatibility

Processes PP, PE, PET packing films, rigid plastics, and post-consumer waste with adjustable temperature control (100-300°C) for optimal material flow.

Energy-Smart Operation

Integrated frequency conversion drive reduces power consumption by 15-20% versus conventional models, with auto-shutdown safety features.

Modular Cleaning System

Quick-disassembly hopper and accessible die head streamline maintenance, reducing downtime between material switches.

Space-Optimized Footprint

Compact 2.1m x 1.5m layout fits small workshops, featuring noise-dampened operation below 75dB for urban facilities.

End-to-End Recycling Solution

Ideal for plastic film manufacturers, recycling plants, and packaging converters to transform scrap into reusable granules for injection molding or extrusion.

Global Compliance Ready

CE-certified with 380V/50Hz and 220V/60Hz voltage options for worldwide deployment.

See More