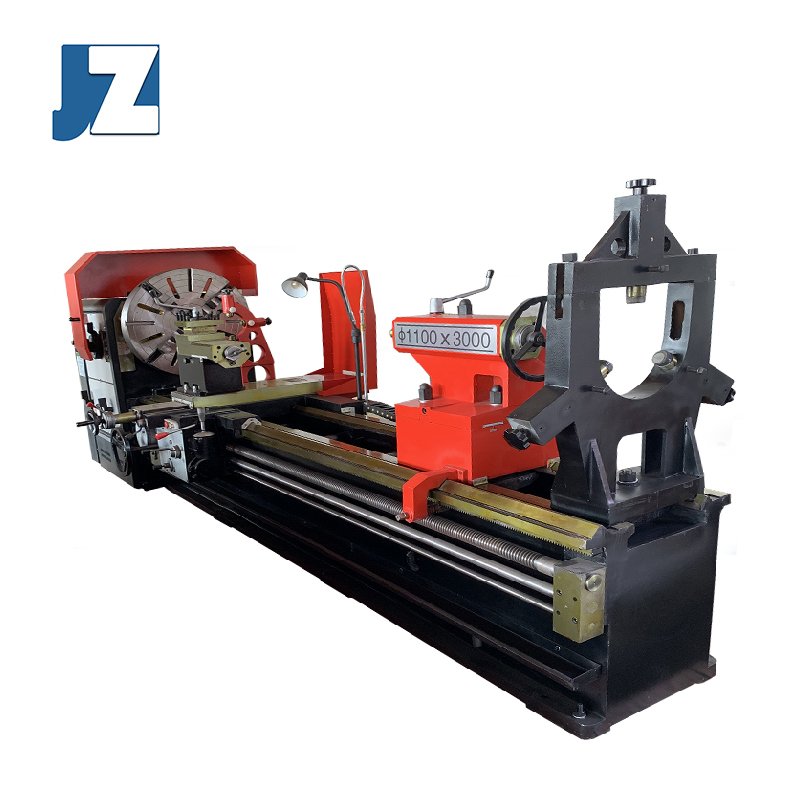

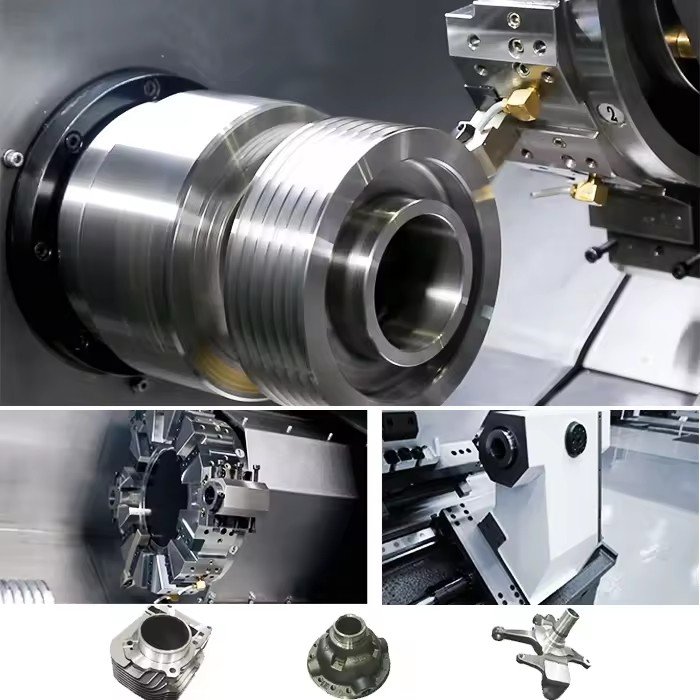

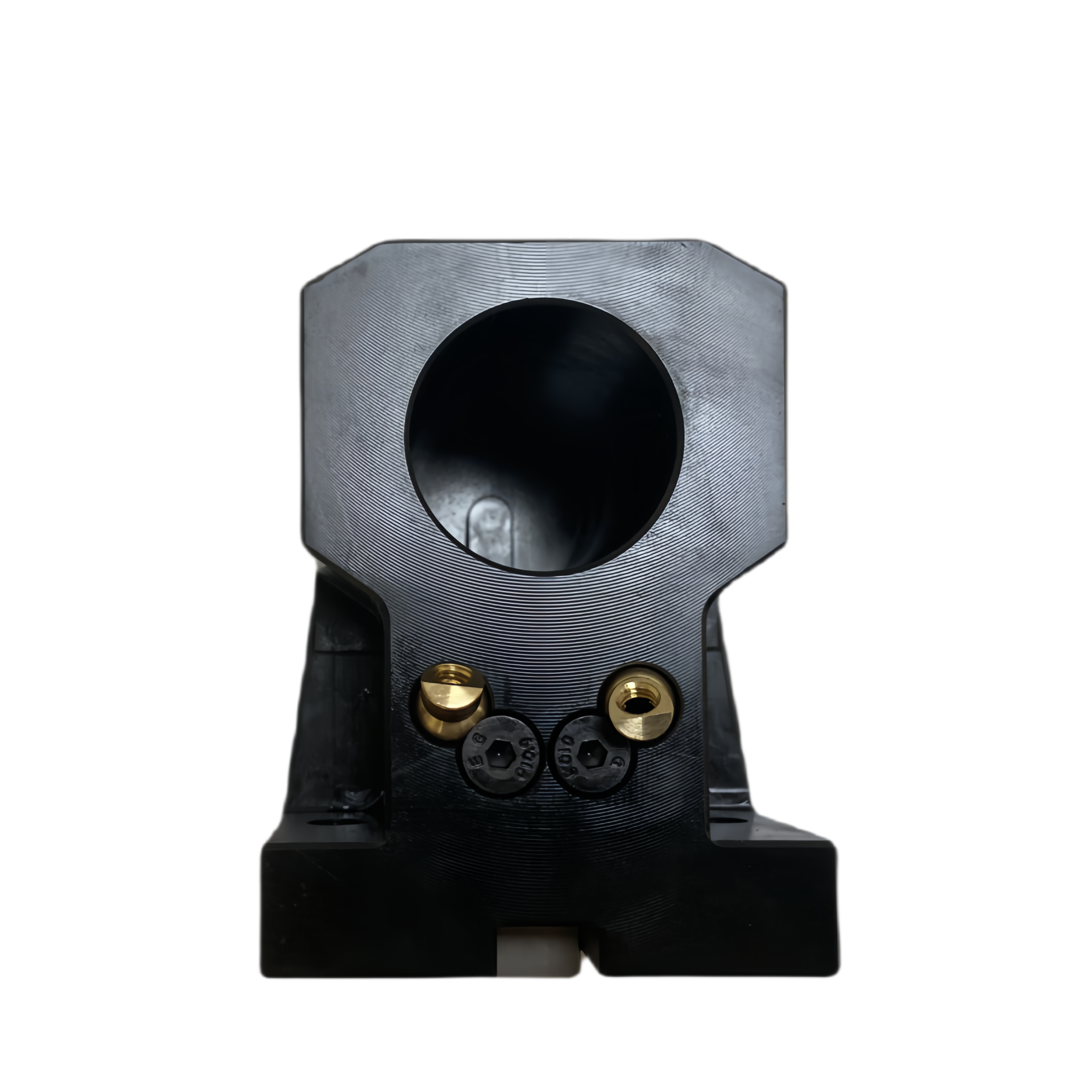

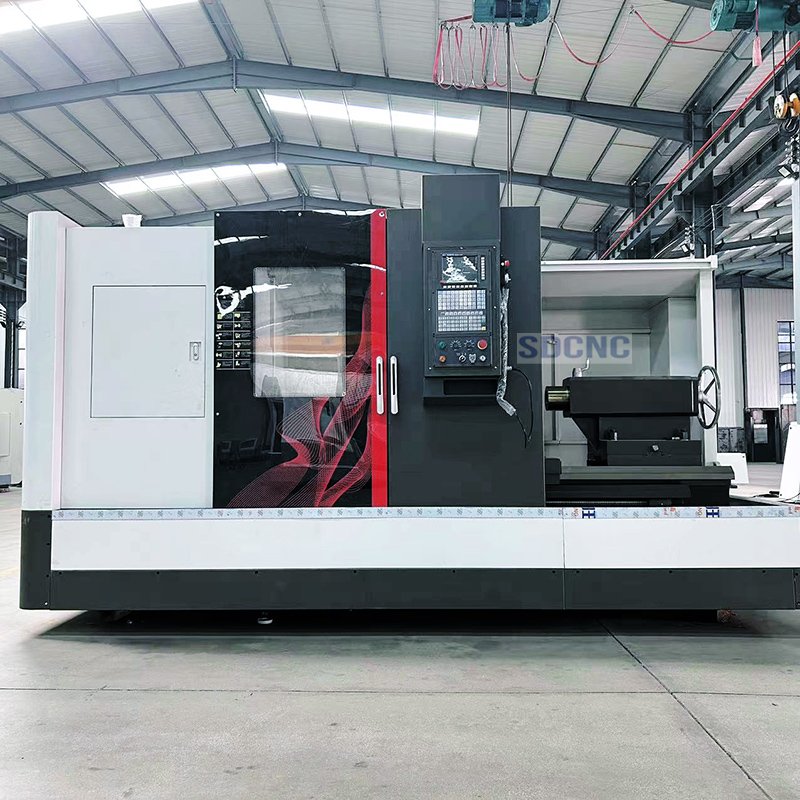

Precision-engineered TK2120 CNC Deep Hole Drilling & Boring Machine delivers ultra-precise boreholes up to 3m depth with ±0.01mm tolerance. High-rigidity cast iron base and hardened steel spindle ensure vibration-free operation for aerospace-grade accuracy.

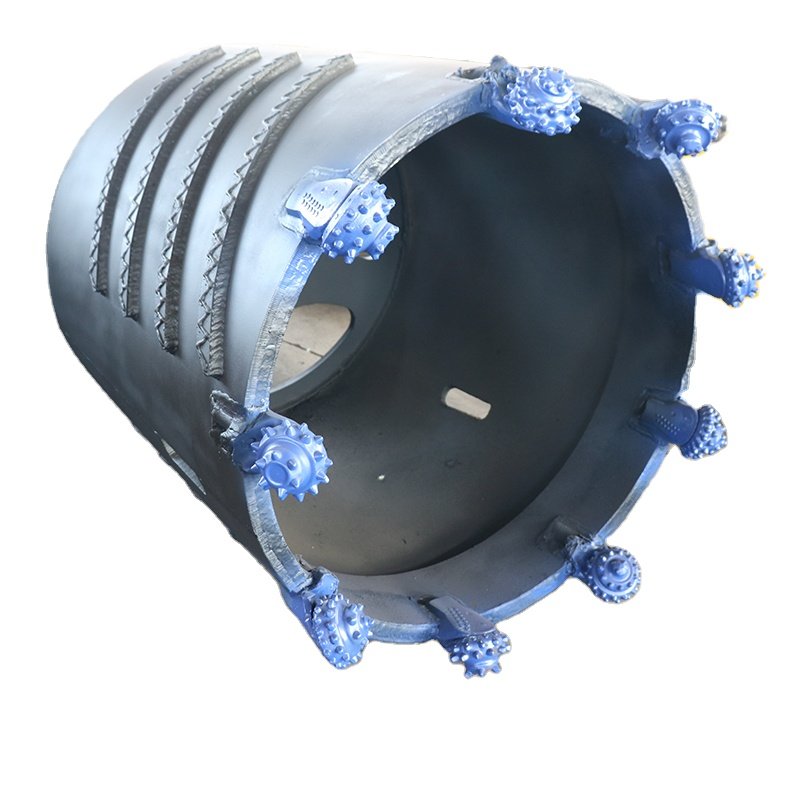

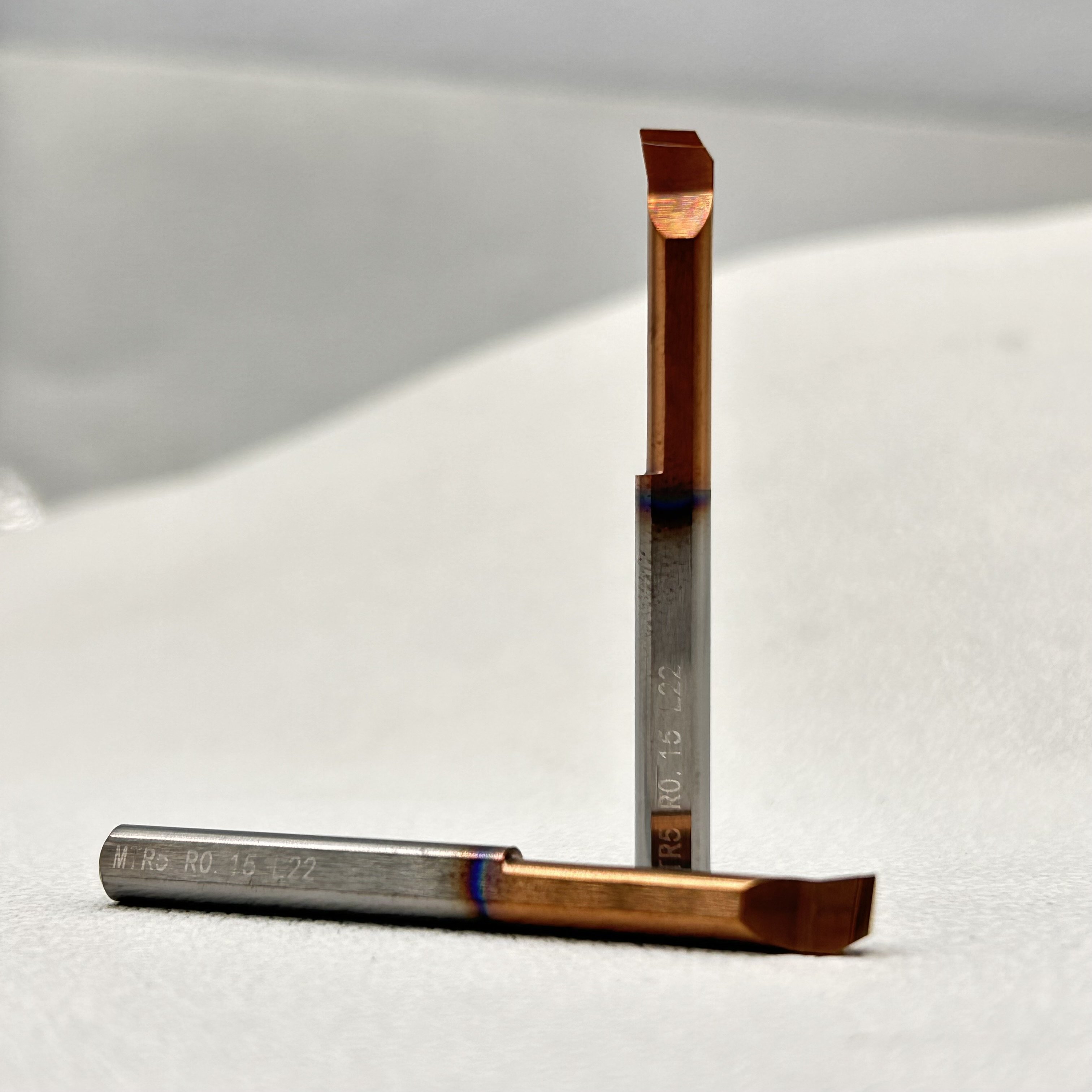

Dual-coolant system with high-pressure oil filtration prevents chip clogging during titanium/alloy machining. Automatic tool changer supports 12 stations for uninterrupted production of hydraulic cylinders/gun barrels.

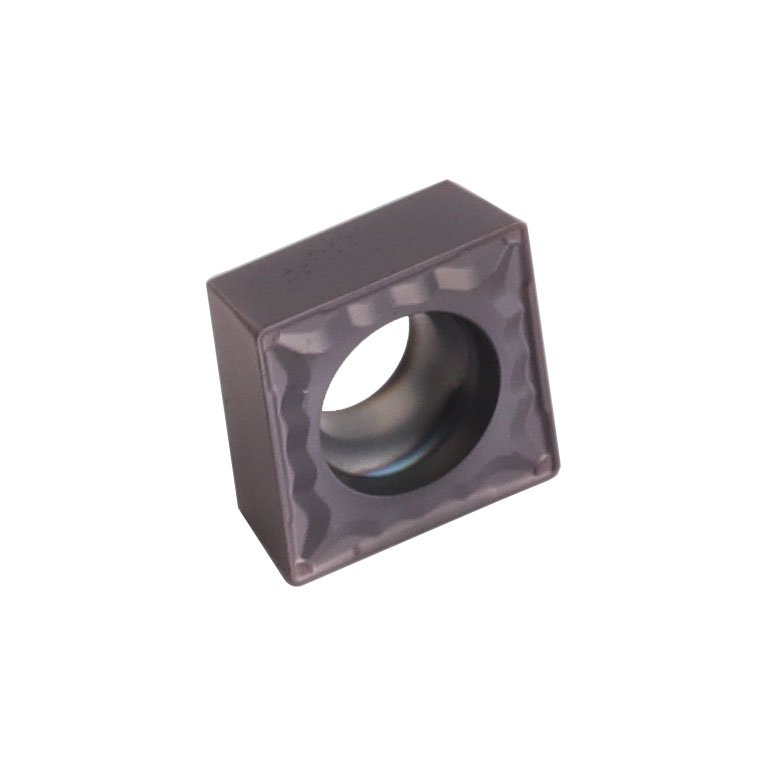

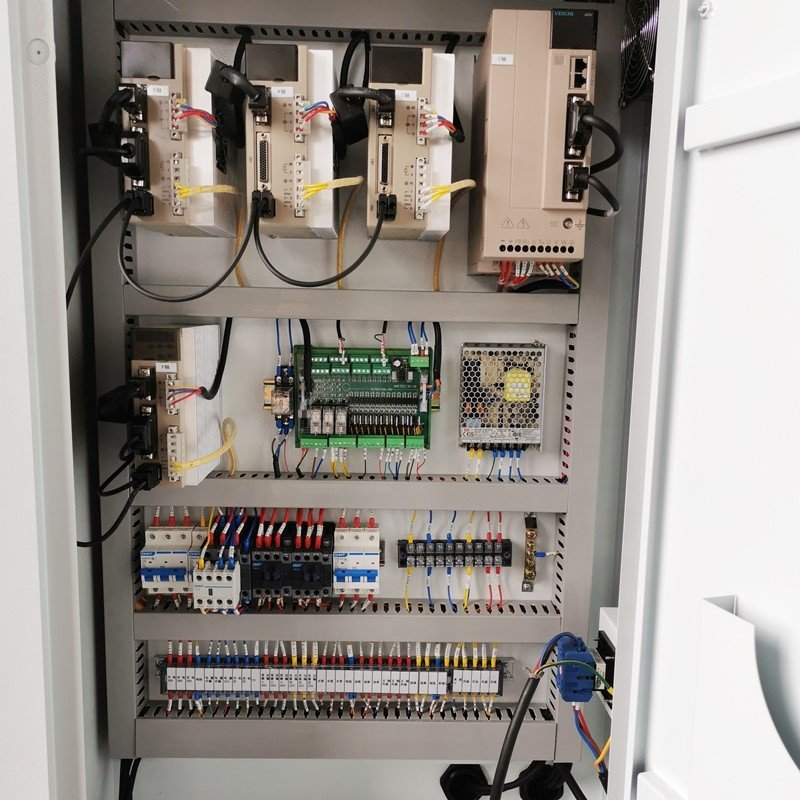

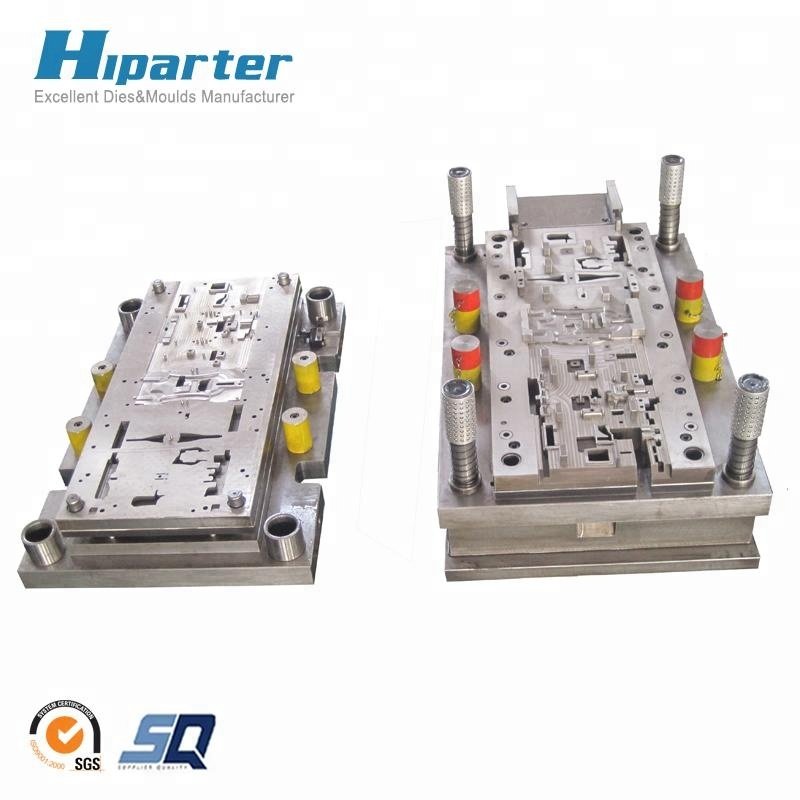

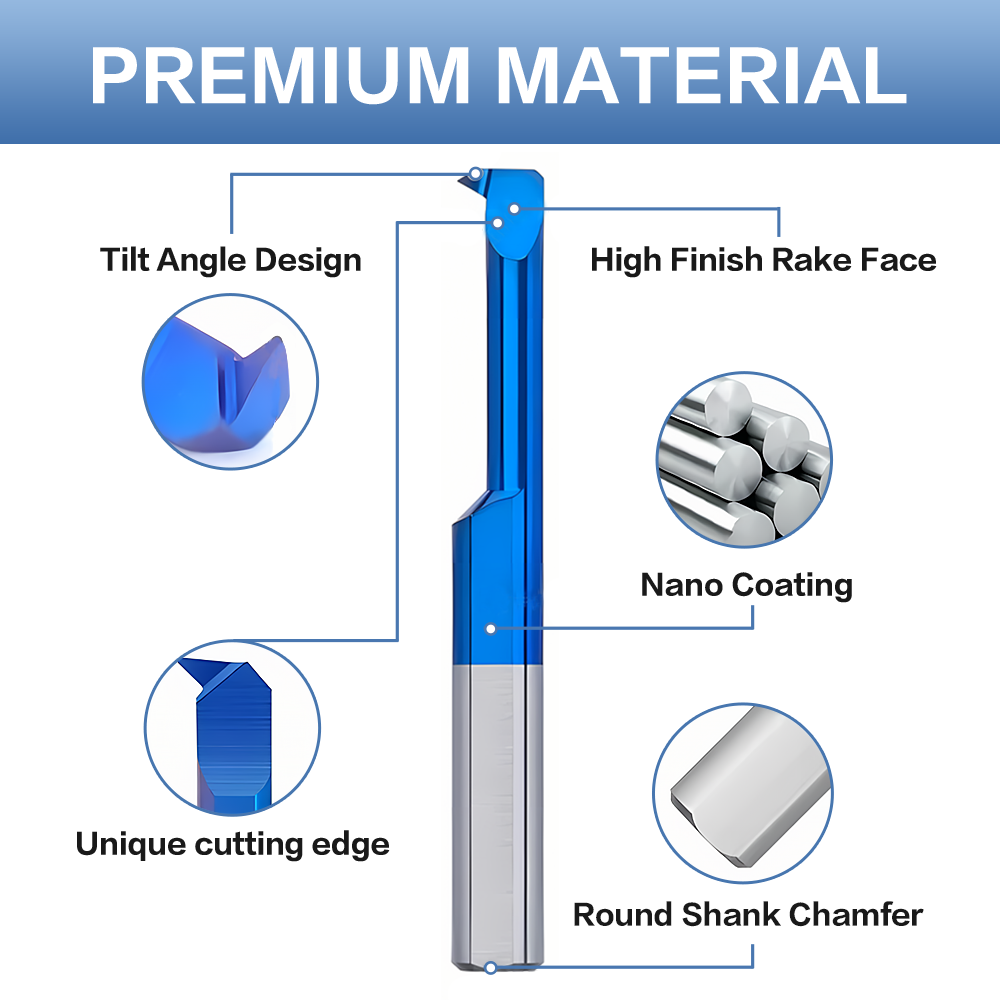

Patented pull-boring technology achieves mirror finishes (Ra 0.4μm) on diesel injectors/mold cores. Touchscreen FANUC control enables parametric programming for batch processing.

Industrial 15kW spindle with 3,000rpm handles stainless steel/Inconel. Includes laser alignment kit and thermal compensation for 24/7 gearbox housing production.

Dust-proof linear guides and centralized lubrication extend lifespan to 100,000 operating hours. CE-certified with emergency brake for automotive crankshaft applications.

Exclusive wholesale pricing for bulk orders - direct from manufacturer with ISO 9001 certification. Ships globally with on-site installation support.

Recent Purchase

View All

Customer Reviews

TK2120*3m CNC Deep Hole Drilling and Boring Machine Tool Deep Hole Pull Boring Machine

$100000$169560.85-41.02%

Drilling Capacity:

80 mm

Quantity:

Add to Cart

Wishlist

Features

See More