Recent Purchase

View All

Customer Reviews

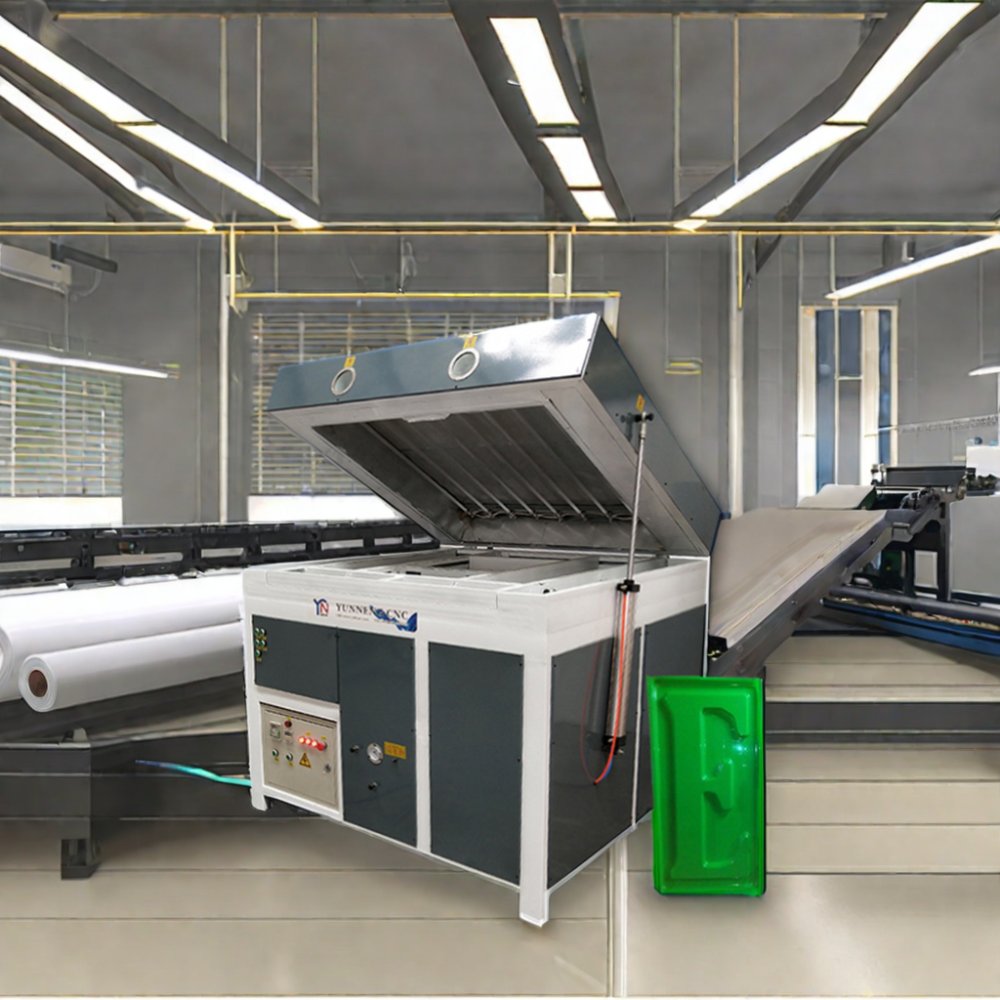

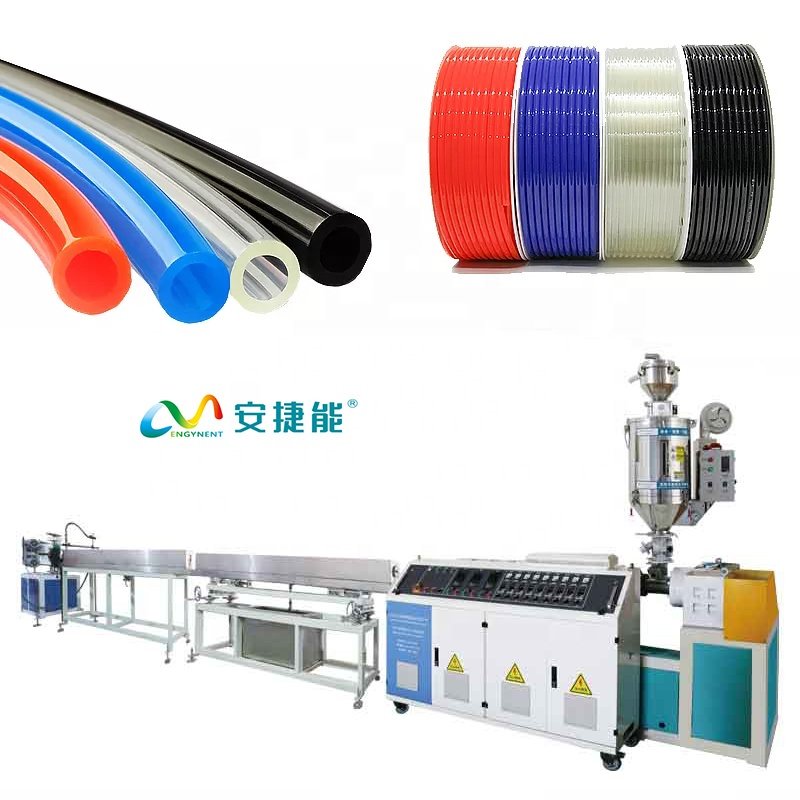

pp pet filament extruder twin screw extruder system for polyester fiber filling pillow cushion

$13600$17020.33-20.1%

Output (kg/h):

150

500

50

250

280

80

300

120

30

200

450

400

100

20

350

60

180

Model Number:

MK-PJ45

MK-PJ60

MK-PJ50

Quantity:

Add to Cart

Wishlist

Features

High-Performance PP Pet Filament Extruder Twin Screw System for Polyester Fiber Filling

Premium Twin Screw Design

Engineered with precision-ground twin screws for consistent, high-output filament production, ensuring uniform fiber thickness and superior melt homogenization. Ideal for industrial-scale pillow and cushion filling applications.

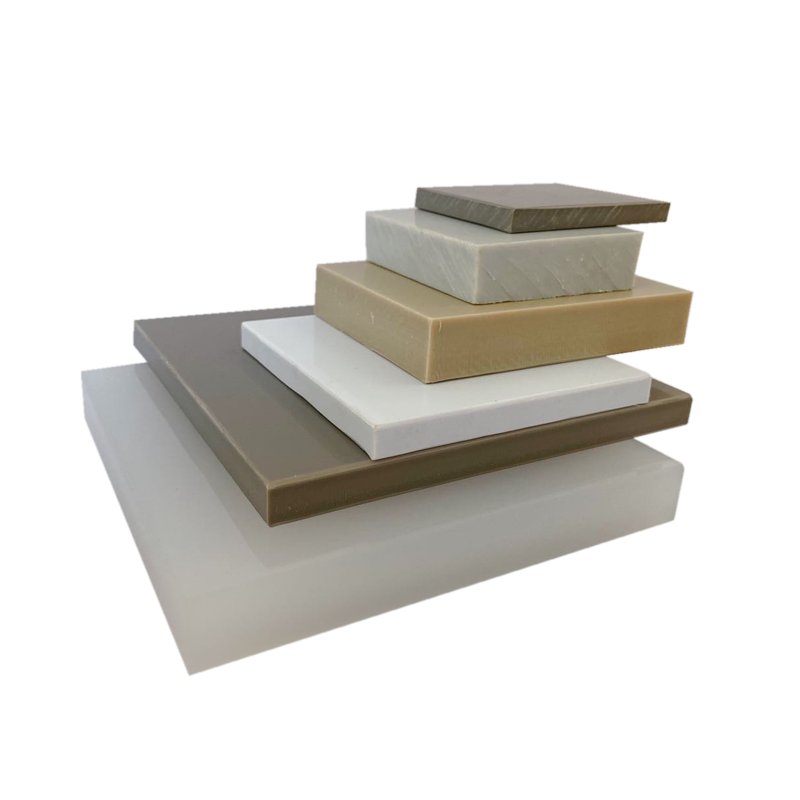

Durable Construction & Advanced Materials

Built with hardened alloy steel components and corrosion-resistant coatings, delivering long-lasting performance under continuous operation. Features optimized heating zones for precise temperature control of PP/polyester materials.

Efficiency-Optimized Production

Capable of processing recycled PET flakes or virgin PP pellets into fluffy fiber fills at 50-300kg/hour. Reduces energy consumption by 15% vs single-screw systems while maintaining fiber loftiness and resilience.

Versatile End-Use Applications

Perfect for manufacturing hypoallergenic bedding fills, automotive seat cushions, plush toy stuffing, and thermal-insulation materials. Compatible with eco-friendly biodegradable polyester fibers.

Plug-and-Play Industrial Solution

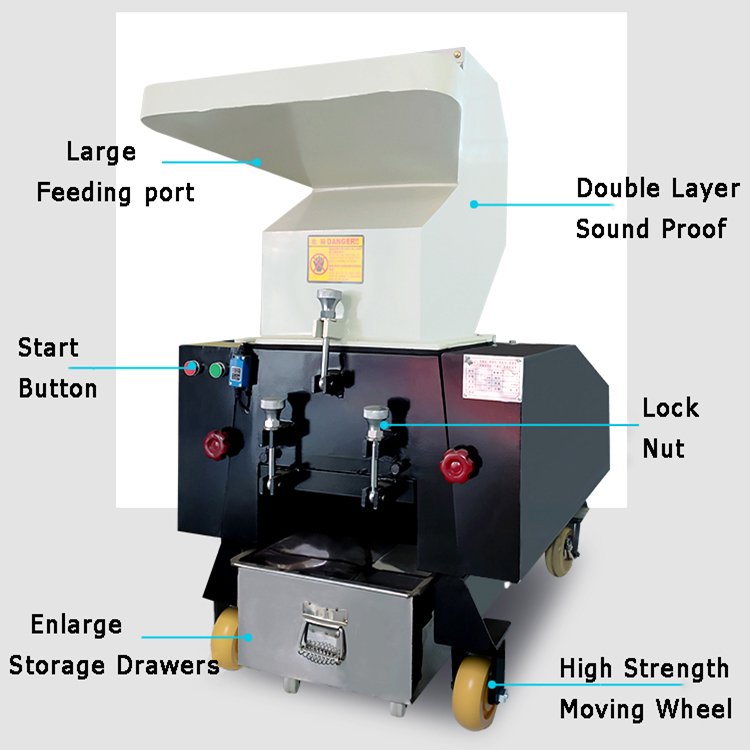

Includes integrated cutting system and automatic winding option. Minimal maintenance required with quick-release screw assembly for cleaning. CE-certified safety guards standard.

Bulk Order Advantage

Direct factory pricing with MOQ flexibility. Customizable screw configurations (L/D ratio 28-40) available for specialized fiber textures. Ships with 12-month warranty and technical support.

See More