Recent Purchase

ifh***

Production Capacity (Pieces/8 hours):50000m3-300000m3;Model Number:AAC block machine;Power:AAC block machine;

$24208084.24

49 days ago

kps***

Production Capacity (Pieces/8 hours):50000m3-300000m3;Model Number:AAC block machine;Power:AAC block machine;

$9078031.59

33 days ago

uwt***

Production Capacity (Pieces/8 hours):50000m3-300000m3;Model Number:AAC block machine;Power:AAC block machine;

$3026010.53

28 days ago

vyv***

Production Capacity (Pieces/8 hours):50000m3-300000m3;Model Number:AAC block machine;Power:AAC block machine;

$18156063.18

21 days ago

raf***

Production Capacity (Pieces/8 hours):50000m3-300000m3;Model Number:AAC block machine;Power:AAC block machine;

$9078031.59

48 days ago

qpf***

Production Capacity (Pieces/8 hours):50000m3-300000m3;Model Number:AAC block machine;Power:AAC block machine;

$30260105.30

41 days ago

eez***

Production Capacity (Pieces/8 hours):50000m3-300000m3;Model Number:AAC block machine;Power:AAC block machine;

$21182073.71

32 days ago

uaw***

Production Capacity (Pieces/8 hours):50000m3-300000m3;Model Number:AAC block machine;Power:AAC block machine;

$3026010.53

33 days ago

uau***

Production Capacity (Pieces/8 hours):50000m3-300000m3;Model Number:AAC block machine;Power:AAC block machine;

$18156063.18

10 days ago

kdw***

Production Capacity (Pieces/8 hours):50000m3-300000m3;Model Number:AAC block machine;Power:AAC block machine;

$30260105.30

29 days ago

View All

Customer Reviews

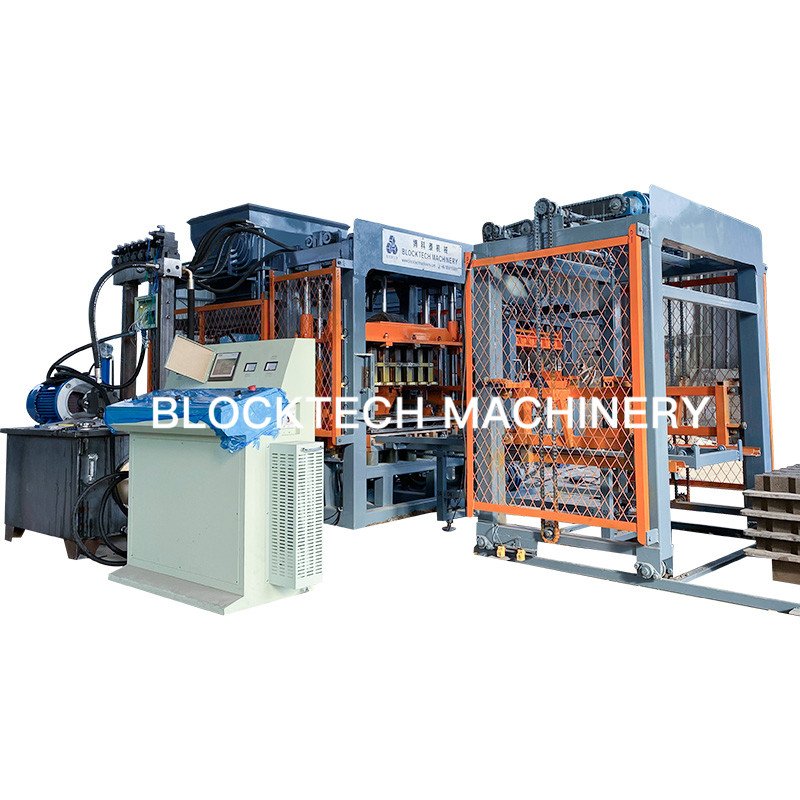

AAC Block Production Line for Building Blocks and Panels in Ytong Aerated Concrete Ytong Modular Panel System

$1600000$3026010.53-47.13%

Production Capacity (Pieces/8 hours):

50000m3-300000m3

Model Number:

AAC block machine

Power:

AAC block machine

Quantity:

Add to Cart

Wishlist

Features

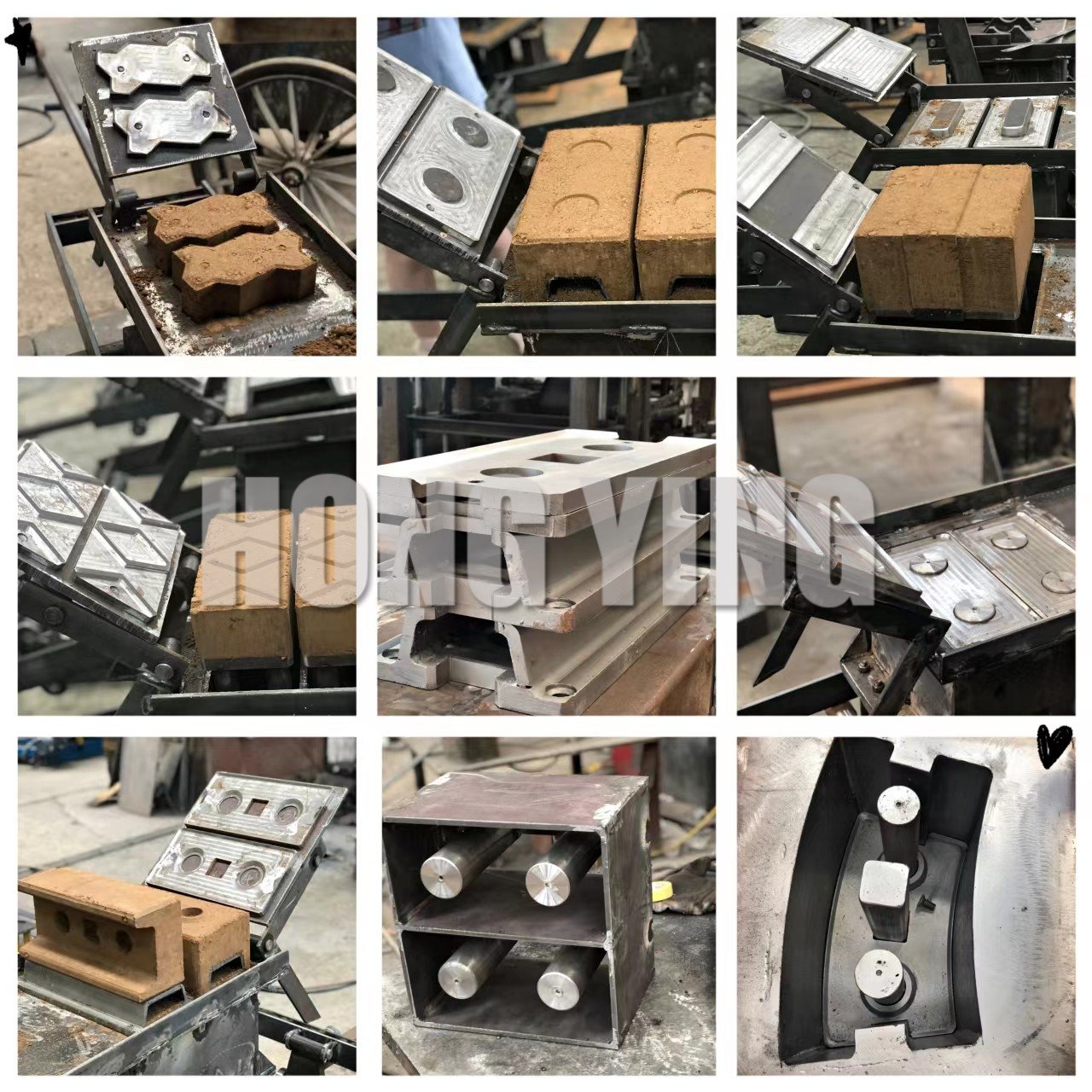

Ytong AAC Block Production Line for Building & Panel Systems

High-performance automated line for precision manufacturing of lightweight, durable AAC blocks and panels. Advanced German-engineered cutting technology ensures ±1mm dimensional accuracy for seamless modular construction. Ultra-low density (400-650kg/m³) with superior thermal insulation (λ 0.09-0.14W/mK) and fire resistance (4-hour rating). Eco-friendly composition: 60% recycled fly ash, quartz sand, and non-toxic expansion agents. Integrated steam curing system achieves 4.5N/mm² strength in 12 hours. Customizable output (100-300m³/day) for large-scale housing projects, partition walls, and prefab high-rises. Turnkey solution includes automatic slurry mixing, wire cutting, and stacking robots. ISO-certified, energy-efficient design cuts operational costs by 30% vs traditional lines.

See More