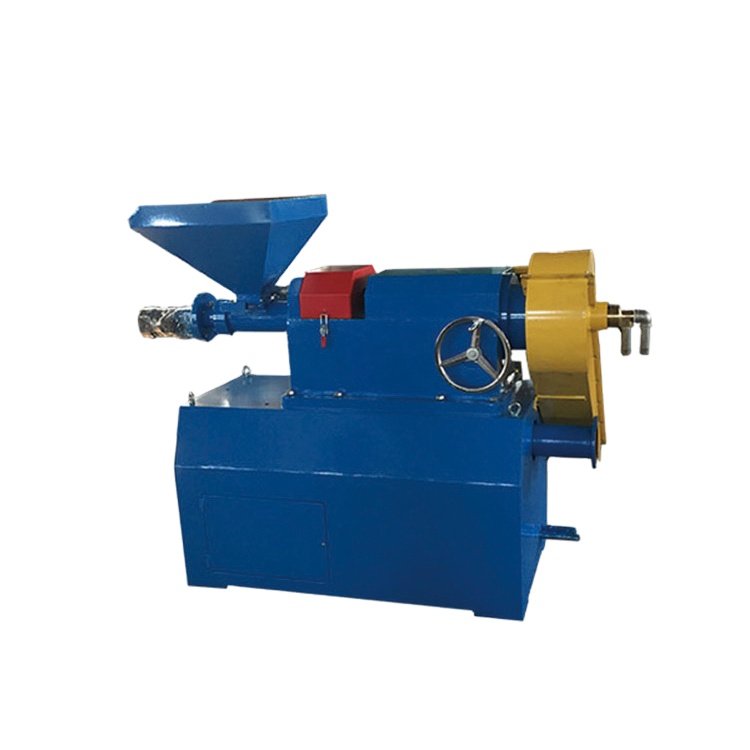

Detergent Soap Powder Making Machine – Automatic Washing Powder Production Line

High-Efficiency Production

– Fully automated system ensures continuous, large-scale detergent powder manufacturing with minimal manual intervention, ideal for industrial-scale operations.

Premium Stainless Steel Build

– Corrosion-resistant 304 stainless steel components guarantee durability and compliance with hygiene standards for long-term use in harsh chemical environments.

Precision Mixing Technology

– Advanced dual-shaft paddle mixer ensures uniform blending of raw materials (e.g., surfactants, sodium carbonate) for consistent powder density and dissolution performance.

Customizable Output

– Adjustable settings for particle size (20-80 mesh) and production capacity (500kg–2T/hour) to meet diverse market demands, from compact packaging to bulk industrial supply.

Energy-Saving Design

– Integrated heat recovery system reduces thermal energy waste during drying, lowering operational costs for high-volume manufacturers.

Multi-Scenario Application

– Suitable for producing laundry powders, dishwashing detergents, and industrial cleaners, catering to commercial laundries, private label brands, and export-focused suppliers.

Plug-and-Play Installation

– Pre-calibrated modules with clear PLC control interface enable quick setup, reducing downtime for factories expanding production lines.

Global Compliance Ready

– Meets ISO 9001 and CE standards, ensuring seamless export to North American, European, and ASEAN markets without regulatory hurdles.

Lowest Total Cost

– Optimized for bulk raw material input (e.g., linear alkylbenzene sulfonate) with <3% waste rate, maximizing ROI for wholesale suppliers prioritizing margin control.

See More